Hobson Technical Hex Bolts Size Chart

ADVERTISEMENT

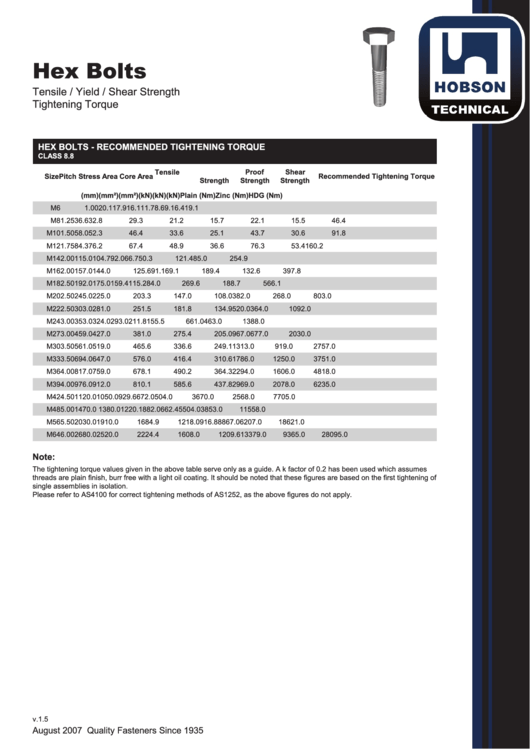

Hex Bolts

Tensile / Yield / Shear Strength

Tightening Torque

HEX BOLTS - RECOMMENDED TIGHTENING TORQUE

CLASS 8.8

Tensile

Proof

Shear

Size

Pitch

Stress Area Core Area

Recommended Tightening Torque

Strength

Strength

Strength

(mm)

(mm²)

(mm²)

(kN)

(kN)

(kN)

Plain (Nm) Zinc (Nm) HDG (Nm)

M6

1.00

20.1

17.9

16.1

11.7

8.6

9.1

6.4

19.1

M8

1.25

36.6

32.8

29.3

21.2

15.7

22.1

15.5

46.4

M10

1.50

58.0

52.3

46.4

33.6

25.1

43.7

30.6

91.8

M12

1.75

84.3

76.2

67.4

48.9

36.6

76.3

53.4

160.2

M14

2.00

115.0

104.7

92.0

66.7

50.3

121.4

85.0

254.9

M16

2.00

157.0

144.0

125.6

91.1

69.1

189.4

132.6

397.8

M18

2.50

192.0

175.0

159.4

115.2

84.0

269.6

188.7

566.1

M20

2.50

245.0

225.0

203.3

147.0

108.0

382.0

268.0

803.0

M22

2.50

303.0

281.0

251.5

181.8

134.9

520.0

364.0

1092.0

M24

3.00

353.0

324.0

293.0

211.8

155.5

661.0

463.0

1388.0

967.0

677.0

2030.0

M27

3.00

459.0

427.0

381.0

275.4

205.0

M30

3.50

561.0

519.0

465.6

336.6

249.1

1313.0

919.0

2757.0

M33

3.50

694.0

647.0

576.0

416.4

310.6

1786.0

1250.0

3751.0

2294.0

1606.0

4818.0

M36

4.00

817.0

759.0

678.1

490.2

364.3

M39

4.00

976.0

912.0

810.1

585.6

437.8

2969.0

2078.0

6235.0

M42

4.50

1120.0

1050.0

929.6

672.0

504.0

3670.0

2568.0

7705.0

M48

5.00

1470.0

1380.0

1220.1

882.0

662.4

5504.0

3853.0

11558.0

M56

5.50

2030.0

1910.0

1684.9

1218.0

916.8

8867.0

6207.0

18621.0

13379.0

9365.0

28095.0

M64

6.00

2680.0

2520.0

2224.4

1608.0

1209.6

Note:

The tightening torque values given in the above table serve only as a guide. A k factor of 0.2 has been used which assumes

threads are plain finish, burr free with a light oil coating. It should be noted that these figures are based on the first tightening of

single assemblies in isolation.

Please refer to AS4100 for correct tightening methods of AS1252, as the above figures do not apply.

v.1.5

August 2007

Quality Fasteners Since 1935

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1