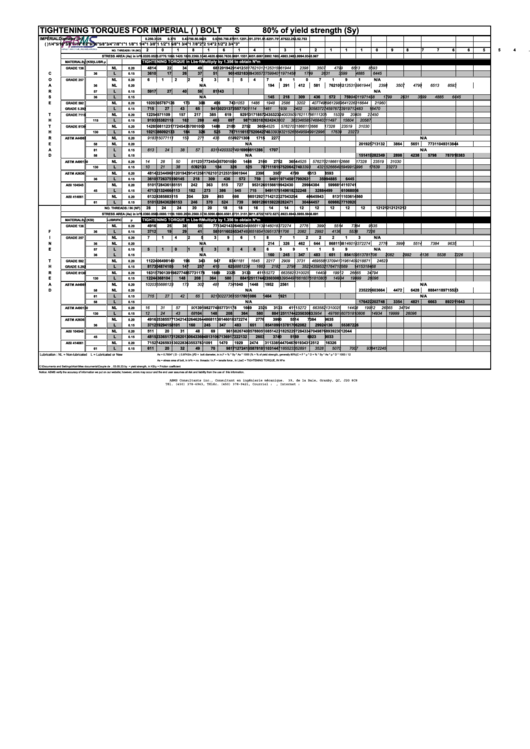

Ambs Imperial (U.s.) Bolts Torque Tightening Chart

ADVERTISEMENT

TIGHTENING TORQUES FOR IMPERIAL (U.S.) BOLTS

80%

of yield strength (Sy)

IMPÉRIAL

Diameter (in)

0.25

0.3125

0.375

0.4375

0.5

0.5625

0.625

0.75

0.875

1

1.125

1.25

1.375

1.5

1.625

1.75

1.875

2

2.25

2.5

2.75

3

(U.S.)

1/4"

5/16"

3/8"

7/16"

1/2"

9/16"

5/8"

3/4"

7/8"

1"

1 1/8"

1 1/4"

1 3/8"

1 1/2"

1 5/8"

1 3/4"

1 7/8"

2"

2 1/4"

2 1/2"

2 3/4"

3"

20

18

16

14

13

12

11

10

9

8

7

7

6

6

5

5

4.5

4.5

4.5

4

4

4

NO. THREADS / IN (NC)

STRESS AREA (As) in in²

0.032

0.052

0.077

0.106

0.142

0.182

0.226

0.334

0.462

0.606

0.763

0.969

1.155

1.405

1.606

1.899

2.160

2.498

3.248

3.999

4.934

5.967

TIGHTENING TORQUE in Lbs·ft

Multiply by 1.356 to obtain N*m

MATERIAL

Sy (KSI)

LUBR.

µ

NL

4

8

14

22

34

49

68

120

194

291

412

581

762

1012

1253

1596

1944

2398

3507

4799

6513

8593

GRADE 1

36

0.20

C

L

3

6

10

17

26

37

51

90

145

218

309

436

572

759

940

1197

1458

1799

2631

3599

4885

6445

36

0.15

O

NL

6

12

22

35

54

78

107

191

N/A

GRADE 2

57

0.20

A

NL

N/A

194

291

412

581

762

1012

1253

1596

1944

2398

3507

4799

6513

8593

36

0.20

R

L

5

9

17

27

40

58

81

143

N/A

57

0.15

S

L

N/A

145

218

309

436

572

759

940

1197

1458

1799

2631

3599

4885

6445

36

0.15

E

NL

10

20

36

57

87

126

173

308

496

743

1053

1486

1948

2586

3202

4077

4969

6129

8964

12263

16644

21960

GRADE 5

92

0.20

L

7

15

27

43

65

94

130

231

372

557

790

1114

1461

1939

2402

3058

3727

4597

6723

9197

12483

16470

GRADE 5.2

92

0.15

T

NL

12

25

45

71

109

157

217

385

619

929

1317

1857

2435

3232

4003

5097

6211

7661

11205

15329

20805

27450

GRADE 7

115

0.20

H

L

9

19

33

53

82

118

162

288

465

697

987

1393

1826

2424

3002

3823

4658

5746

8403

11497

15604

20587

115

0.15

T

NL

14

28

50

81

123

177

245

435

700

1050

1488

2100

2752

3654

4525

5762

7021

8661

12666

17328

23519

31030

GRADE 8

130

0.20

H

L

10

21

38

60

92

133

184

326

525

787

1116

1575

2064

2740

3393

4321

5266

6495

9499

12996

17639

23273

130

0.15

R

NL

9

18

31

50

77

111

153

271

436

654

927

1308

1715

2277

N/A

ASTM A449

81

0.20

E

NL

N/A

2019

2571

3132

3864

5651

7731

10493

13844

58

0.20

A

L

6

13

24

38

57

83

114

203

327

491

696

981

1286

1707

N/A

81

0.15

D

L

N/A

1514

1928

2349

2898

4238

5798

7870

10383

58

0.15

NL

14

28

50

81

123

177

245

435

700

1050

1488

2100

2752

3654

4525

5762

7021

8661

12666

17328

23519

31030

ASTM A490

130

0.20

L

10

21

38

60

92

133

184

326

525

787

1116

1575

2064

2740

3393

4321

5266

6495

9499

12996

17639

23273

130

0.15

NL

4

8

14

22

34

49

68

120

194

291

412

581

762

1012

1253

1596

1944

2398

3507

4799

6513

8593

ASTM A36

36

0.20

L

3

6

10

17

26

37

51

90

145

218

309

436

572

759

940

1197

1458

1799

2631

3599

4885

6445

36

0.15

NL

5

10

17

28

43

61

85

151

242

363

515

727

953

1265

1566

1994

2430

2998

4384

5998

8141

10741

AISI 1045

45

0.20

L

4

7

13

21

32

46

64

113

182

273

386

545

715

949

1175

1496

1823

2248

3288

4499

6106

8056

45

0.15

NL

6

13

24

38

58

83

115

204

329

493

698

985

1292

1714

2123

2704

3294

4064

5943

8131

11036

14560

AISI 4140

61

0.20

L

5

10

18

28

43

62

86

153

246

370

524

739

969

1286

1592

2028

2471

3048

4457

6098

8277

10920

61

0.15

28

24

24

20

20

18

18

16

14

14

12

12

12

12

12

12

12

12

12

12

12

12

NO. THREADS / IN (NF)

STRESS AREA (As) in in²

0.036

0.058

0.088

0.119

0.160

0.203

0.256

0.373

0.509

0.680

0.856

1.073

1.315

1.581

1.872

2.187

2.527

2.892

3.694

4.595

5.594

6.691

TIGHTENING TORQUE in Lbs·ft

Multiply by 1.356 to obtain N*m

MATERIAL

Sy (KSI)

LUBRIFIC

µ

NL

4

9

16

25

38

55

77

134

214

326

462

644

868

1138

1460

1837

2274

2776

3990

5514

7384

9635

GRADE 1

36

0.20

F

L

3

7

12

19

29

41

58

101

160

245

347

483

651

854

1095

1378

1706

2082

2992

4136

5538

7226

36

0.15

I

NL

7

14

25

39

61

87

122

213

N/A

GRADE 2

57

0.20

N

NL

N/A

214

326

462

644

868

1138

1460

1837

2274

2776

3990

5514

7384

9635

36

0.20

E

L

5

10

19

30

46

65

91

159

N/A

57

0.15

L

N/A

160

245

347

483

651

854

1095

1378

1706

2082

2992

4136

5538

7226

36

0.15

T

NL

11

22

40

64

98

140

196

343

547

834

1181

1645

2217

2909

3731

4695

5813

7094

10196

14092

18871

24623

GRADE 5

92

0.20

H

L

8

17

30

48

74

105

147

257

410

625

886

1234

1663

2182

2798

3522

4359

5321

7647

10569

14153

18468

GRADE 5.2

92

0.15

R

NL

16

31

57

90

139

198

277

485

773

1178

1669

2325

3133

4111

5272

6635

8213

10025

14408

19912

26665

34794

GRADE 8

130

0.20

E

L

12

24

43

68

104

148

208

364

580

884

1251

1744

2350

3083

3954

4976

6160

7518

10806

14934

19999

26096

130

0.15

A

NL

10

20

36

56

86

123

173

302

481

734

1040

1448

1952

2561

N/A

ASTM A449

81

0.20

D

NL

N/A

2352

2960

3664

4472

6428

8884

11897

15523

58

0.20

L

7

15

27

42

65

92

130

227

361

551

780

1086

1464

1921

N/A

81

0.15

L

N/A

1764

2220

2748

3354

4821

6663

8922

11643

58

0.15

NL

16

31

57

90

139

198

277

485

773

1178

1669

2325

3133

4111

5272

6635

8213

10025

14408

19912

26665

34794

ASTM A490

130

0.20

L

12

24

43

68

104

148

208

364

580

884

1251

1744

2350

3083

3954

4976

6160

7518

10806

14934

19999

26096

130

0.15

NL

4

9

16

25

38

55

77

134

214

326

462

644

868

1138

1460

1837

2274

2776

3990

5514

7384

9635

ASTM A36

36

0.20

L

3

7

12

19

29

41

58

101

160

245

347

483

651

854

1095

1378

1706

2082

2992

4136

5538

7226

36

0.15

NL

5

11

20

31

48

69

96

168

267

408

578

805

1085

1423

1825

2297

2843

3470

4987

6893

9230

12044

AISI 1045

45

0.20

L

4

8

15

23

36

51

72

126

201

306

433

604

813

1067

1369

1722

2132

2603

3740

5169

6923

9033

45

0.15

NL

7

15

27

42

65

93

130

228

363

553

783

1091

1470

1929

2474

3113

3854

4704

6761

9343

12512

16326

AISI 4140

61

0.20

L

6

11

20

32

49

70

98

171

272

415

587

818

1103

1447

1855

2335

2891

3528

5070

7007

9384

12245

61

0.15

Lubrication : NL = Non-lubricated

L = Lubricated or New

As = 0.7854* ( D - ( 0.9743/n ))²

D = bolt diameter, in in.

F = % * Sy * As * 1000 (% = % of yield strength, generally 80%)

C = F * µ * D = % * Sy * As * µ * D * 1000 / 12

As = stress area of bolt, in in²

n = no. threads / in.

F = tensile force , in Lbs

C = TIGHTENING TORQUE, IN N*m

C:\Documents and Settings\Alain\Mes documents\Couple de serrage.xls, 03.05.23 by A.S.

Sy = yield strength, in KSI

µ = Friction coefficient

Notice: ABMS verify the accuracy of information we put on our website; however, errors may occur and the end user assumes all risk and liability from the use of this information.

ABMS Consultants inc., Consultant en ingénierie mécanique.

39, de la Baie, Granby, QC, J2G 8C8

Tél. (450) 378-6963, Téléc. (450) 378-9421, Courriel : alain.scuvee@abms.ca, Internet :

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1 2

2