Standard Operating Procedure Page 2

Download a blank fillable Standard Operating Procedure in PDF format just by clicking the "DOWNLOAD PDF" button.

Open the file in any PDF-viewing software. Adobe Reader or any alternative for Windows or MacOS are required to access and complete fillable content.

Complete Standard Operating Procedure with your personal data - all interactive fields are highlighted in places where you should type, access drop-down lists or select multiple-choice options.

Some fillable PDF-files have the option of saving the completed form that contains your own data for later use or sending it out straight away.

ADVERTISEMENT

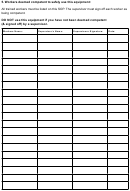

2. Safe Operation

(Describe the correct & safe use of the equipment. Break the operation down into simple

steps from start to finish. Include all safety measures required eg. cut off switches, RCDs to

be used etc)

1. Correct disc/wheel size must be used. Ensure you have the correct rpm rating and disc size. For this grinder a 125mm disc

with a 22mm hole diameter, with a rpm rating of 6,970 must be used. If you have to remove the guard to fit the disc then you

have selected the wrong disc/wheel.

2. Correct disc/wheel must be selected for the work you are doing eg. a thin cutting disc usually 3mm thick for cutting metal,

a wire wheel for buffing/cleaning, a thick grinding disc for rounding off sharp edges. Do not use a cutting disc for cleaning or

buffing because using the wrong disc can lead to it weakening and cause it to shatter.

3. Check to see if the power source you are using is RCD protected. If not, a portable RCD must be used. Check the RCD is

working by plugging it in and press the test button to make sure it trips. Do not use this grinder if it is not RCD protected.

4. Ensure the trigger switch is working correctly, the grinder should stop as soon as you release the trigger. If the grinder stays

in operation or the trigger gets stuck, report this to your supervisor immediately and take the grinder out of service.

5. Correctly set up your work area before operating this grinder. Ensure the surface/material you are about to work on is set up

on a level and firm surface, consider using a vice or clamps to hold it in place. Ensure the work area is clean and free from

any combustible materials, as these present a fire hazard during operation. Set up screens as required to protect other workers

from sparks generated.

6. When using the grinder ensure the movable guard is in a position that protects you from the spray of sparks and also allows

you full access to the work surface.

7. Always use the outside of the disc when cutting/grinding. Never use the center of a disc to grind an edge down rather than

changing a disc because this will significantly weaken the disc and will increase the likelihood of it shattering during

operation.

8. When stopping a disc/wheel, release the trigger and allow the grinder to come to a stop on its own. Do not apply pressure to

make it stop as this can cause the disc to shatter or get caught/jammed. Ensure the grinder has stopped moving before

changing work positions, as you may come in contact with a spinning disc causing personal injury or property damage.

9. If the grinder becomes overheated eg. too hot to handle, or you notice any sparks or smoke, stop work immediately and

report to your supervisor as you may require a different tool to carry out your task safely.

10. Stop work half an hour before leaving just to make sure no sparks created have started a fire.

11. No disc/wheel changes are to be made while the grinder is still connected to a power source.

3. After Use (What must be carried out after work is complete to ensure the safety of the

equipment & other workers in the area?)

Steps for safe shut down of equipment:

Ensure the grinder has come to a complete stop and then pull the plug out from the power source to ensure no accidental

operation. Place on a level surface to reduce the risk of the grinder falling and being damaged.

Cleaning/housekeeping required:

Clean up all off-cuts and ensure any sparks created have cooled down and have been cleaned up. Ensure all PPE is thoroughly

cleaned after use.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Legal

1

1 2

2 3

3 4

4

![Standard Operating Procedure [sop] Worksheet Standard Operating Procedure [sop] Worksheet](https://data.formsbank.com/pdf_docs_html/310/3101/310102/page_1_thumb.png)