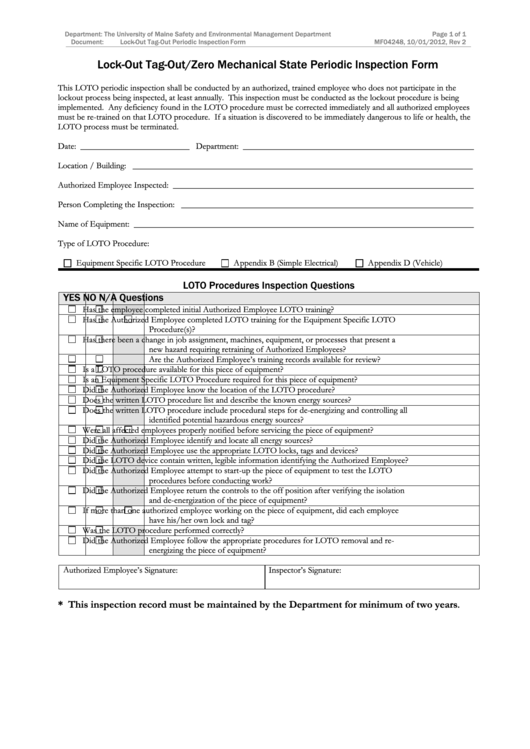

Mf04248 Lock-Out Tag-Out/zero Mechanical State Periodic Inspection Form

ADVERTISEMENT

Department:

The University of Maine Safety and Environmental Management Department

Page 1 of 1

Document:

Lock-Out Tag-Out Periodic Inspection Form

MF04248, 10/01/2012, Rev 2

Lock-Out Tag-Out/Zero Mechanical State Periodic Inspection Form

This LOTO periodic inspection shall be conducted by an authorized, trained employee who does not participate in the

lockout process being inspected, at least annually. This inspection must be conducted as the lockout procedure is being

implemented. Any deficiency found in the LOTO procedure must be corrected immediately and all authorized employees

must be re-trained on that LOTO procedure. If a situation is discovered to be immediately dangerous to life or health, the

LOTO process must be terminated.

Date: _________________________ Department: _____________________________________________________

Location / Building: ______________________________________________________________________________

Authorized Employee Inspected: _____________________________________________________________________

Person Completing the Inspection: ___________________________________________________________________

Name of Equipment: ______________________________________________________________________________

Type of LOTO Procedure:

Equipment Specific LOTO Procedure

Appendix B (Simple Electrical)

Appendix D (Vehicle)

LOTO Procedures Inspection Questions

YES

NO

N/A

Questions

Has the employee completed initial Authorized Employee LOTO training?

Has the Authorized Employee completed LOTO training for the Equipment Specific LOTO

Procedure(s)?

Has there been a change in job assignment, machines, equipment, or processes that present a

new hazard requiring retraining of Authorized Employees?

Are the Authorized Employee’s training records available for review?

Is a LOTO procedure available for this piece of equipment?

Is an Equipment Specific LOTO Procedure required for this piece of equipment?

Did the Authorized Employee know the location of the LOTO procedure?

Does the written LOTO procedure list and describe the known energy sources?

Does the written LOTO procedure include procedural steps for de-energizing and controlling all

identified potential hazardous energy sources?

Were all affected employees properly notified before servicing the piece of equipment?

Did the Authorized Employee identify and locate all energy sources?

Did the Authorized Employee use the appropriate LOTO locks, tags and devices?

Did the LOTO device contain written, legible information identifying the Authorized Employee?

Did the Authorized Employee attempt to start-up the piece of equipment to test the LOTO

procedures before conducting work?

Did the Authorized Employee return the controls to the off position after verifying the isolation

and de-energization of the piece of equipment?

If more than one authorized employee working on the piece of equipment, did each employee

have his/her own lock and tag?

Was the LOTO procedure performed correctly?

Did the Authorized Employee follow the appropriate procedures for LOTO removal and re-

energizing the piece of equipment?

Authorized Employee’s Signature:

Inspector’s Signature:

* This inspection record must be maintained by the Department for minimum of two years

.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1