Aerial Lift Operator Job Performance Measure Form

ADVERTISEMENT

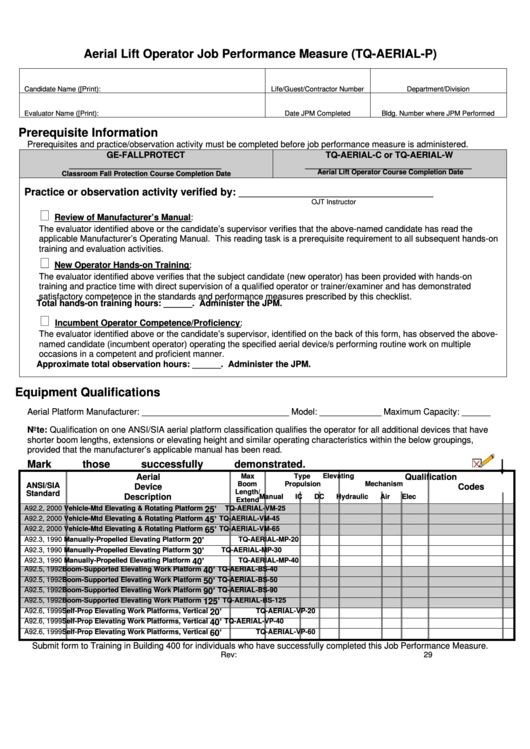

Aerial Lift Operator Job Performance Measure (TQ-AERIAL-P)

Candidate Name ([Print):

Life/Guest/Contractor Number

Department/Division

Evaluator Name ([Print):

Date JPM Completed

Bldg. Number where JPM Performed

Prerequisite Information

Prerequisites and practice/observation activity must be completed before job performance measure is administered.

GE-FALLPROTECT

TQ-AERIAL-C or TQ-AERIAL-W

________________________________

___________________________________

Classroom Fall Protection Course Completion Date

Aerial Lift Operator Course Completion Date

Practice or observation activity verified by: __________________________________

OJT Instructor

Review of Manufacturer’s Manual:

The evaluator identified above or the candidate’s supervisor verifies that the above-named candidate has read the

applicable Manufacturer’s Operating Manual. This reading task is a prerequisite requirement to all subsequent hands-on

training and evaluation activities.

New Operator Hands-on Training:

The evaluator identified above verifies that the subject candidate (new operator) has been provided with hands-on

training and practice time with direct supervision of a qualified operator or trainer/examiner and has demonstrated

satisfactory competence in the standards and performance measures prescribed by this checklist.

Total hands-on training hours: ______. Administer the JPM.

Incumbent Operator Competence/Proficiency:

The evaluator identified above or the candidate’s supervisor, identified on the back of this form, has observed the above-

named candidate (incumbent operator) operating the specified aerial device/s performing routine work on multiple

occasions in a competent and proficient manner.

Approximate total observation hours: ______. Administer the JPM.

Equipment Qualifications

Aerial Platform Manufacturer: _______________________________ Model: _____________ Maximum Capacity: ______

Note: Qualification on one ANSI/SIA aerial platform classification qualifies the operator for all additional devices that have

shorter boom lengths, extensions or elevating height and similar operating characteristics within the below groupings,

provided that the manufacturer’s applicable manual has been read

.

Mark those successfully demonstrated.

Max

Type

Elevating

Aerial

Qualification

Boom

Propulsion

Mechanism

ANSI/SIA

Device

Codes

Length/

Standard

Description

Manual

IC

DC

Hydraulic

Air

Elec

Extend

A92.2, 2000

Vehicle-Mtd Elevating & Rotating Platform

TQ-AERIAL-VM-25

25’

A92.2, 2000

Vehicle-Mtd Elevating & Rotating Platform

TQ-AERIAL-VM-45

45’

A92.2, 2000

Vehicle-Mtd Elevating & Rotating Platform

TQ-AERIAL-VM-65

65’

A92.3, 1990

Manually-Propelled Elevating Platform

TQ-AERIAL-MP-20

20’

A92.3, 1990

Manually-Propelled Elevating Platform

TQ-AERIAL-MP-30

30’

A92.3, 1990

Manually-Propelled Elevating Platform

TQ-AERIAL-MP-40

40’

A92.5, 1992

Boom-Supported Elevating Work Platform

TQ-AERIAL-BS-40

40’

A92.5, 1992

Boom-Supported Elevating Work Platform

TQ-AERIAL-BS-50

50’

A92.5, 1992

Boom-Supported Elevating Work Platform

TQ-AERIAL-BS-90

90’

A92.5, 1992

Boom-Supported Elevating Work Platform

TQ-AERIAL-BS-125

125’

A92.6, 1999

Self-Prop Elevating Work Platforms, Vertical

20’

TQ-AERIAL-VP-20

A92.6, 1999

Self-Prop Elevating Work Platforms, Vertical

TQ-AERIAL-VP-40

40’

A92.6, 1999

Self-Prop Elevating Work Platforms, Vertical

60’

TQ-AERIAL-VP-60

Submit form to Training in Building 400 for individuals who have successfully completed this Job Performance Measure.

Rev: 29 March 2011

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2