request

for quote

Light/MediuM-duty RoLL up CoveRs

Date

__________________________________________

Address

_____________________________________________

Company Name __________________________________________

City

___________________________ State/Prov. _________

Contact

__________________________________________

Country

_______________________ Zip/Postal Code _________

Quantity of Covers Needed ___________________________________

Telephone

_____________________ Fax ____________________

E-Mail

_____________________________________________

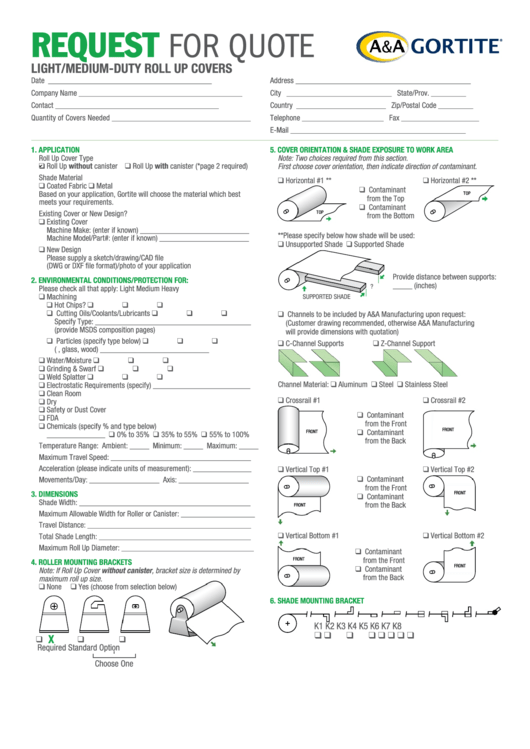

1. AppLiCAtion

5. CoveR oRientAtion & shAde exposuRe to WoRk AReA

Roll Up Cover Type

Note: Two choices required from this section.

q Roll Up without canister q Roll Up with canister (*page 2 required)

First choose cover orientation, then indicate direction of contaminant.

Shade Material

q Horizontal #1 **

q Horizontal #2 **

q Coated Fabric q Metal

q C ontaminant

Based on your application, Gortite will choose the material which best

TOP

from the Top

meets your requirements.

q C ontaminant

Existing Cover or New Design?

TOP

from the Bottom

q Existing Cover

Machine Make: (enter if known) ____________________________

**Please specify below how shade will be used:

Machine Model/Part#: (enter if known) _______________________

q Unsupported Shade q Supported Shade

q New Design

Please supply a sketch/drawing/CAD file

(DWG or DXF file format)/photo of your application

Provide distance between supports:

2. enviRonMentAL Conditions/pRoteCtion foR:

_____ (inches)

?

Please check all that apply:

Light

Medium

Heavy

SUPPORTED SHADE

q Machining

q Hot Chips?

q

q

q

q C utting Oils/Coolants/Lubricants

q

q

q

q C hannels to be included by A&A Manufacturing upon request:

Specify Type: ________________________________________

(Customer drawing recommended, otherwise A&A Manufacturing

(provide MSDS composition pages)

will provide dimensions with quotation)

q P articles (specify type below)

q

q

q

q C-Channel Supports q Z-Channel Support

(e.g. aluminum, glass, wood) ____________________________

q Water/Moisture

q

q

q

q Grinding & Swarf

q

q

q

q Weld Splatter

q

q

q

Channel Material: q Aluminum q Steel q Stainless Steel

q Electrostatic Requirements (specify) _________________________

q Clean Room

q Crossrail #1

q Crossrail #2

q Dry

q Safety or Dust Cover

q C ontaminant

q FDA

from the Front

q Chemicals (specify % and type below)

FRONT

q C ontaminant

FRONT

_______________ q 0% to 35% q 35% to 55% q 55% to 100%

from the Back

Temperature Range: Ambient: _____ Minimum: _____ Maximum: _____

Maximum Travel Speed: ____________________________________

Acceleration (please indicate units of measurement): _______________

q Vertical Top #1

q Vertical Top #2

q C ontaminant

Movements/Day: __________________ Axis: __________________

from the Front

3. diMensions

FRONT

q C ontaminant

Shade Width: ____________________________________________

from the Back

FRONT

Maximum Allowable Width for Roller or Canister: ___________________

Travel Distance: __________________________________________

Total Shade Length: _______________________________________

q Vertical Bottom #1

q Vertical Bottom #2

Maximum Roll Up Diameter: __________________________________

q C ontaminant

from the Front

FRONT

4. RoLLeR Mounting BRACkets

FRONT

q C ontaminant

Note: If Roll Up Cover without canister, bracket size is determined by

from the Back

maximum roll up size.

q None q Yes (choose from selection below)

6. shAde Mounting BRACket

K1

K2

K3

K4

K5

K6

K7

K8

q

q

q

q

q

q

q

q

x

q

q

q

Required

Standard

Option

Choose One

1

1 2

2