AASHTO/AWS D1.5/D1.5M:2010

ANNEX N

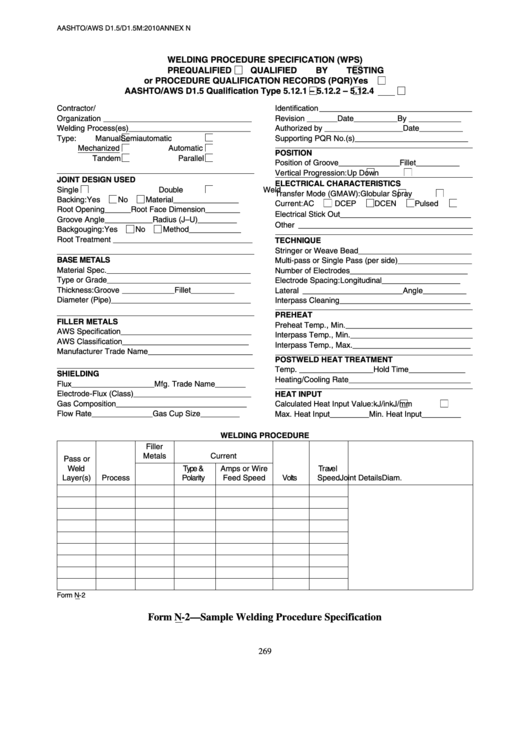

WELDING PROCEDURE SPECIFICATION (WPS)

PREQUALIFIED

QUALIFIED BY TESTING

or PROCEDURE QUALIFICATION RECORDS (PQR) Yes

AASHTO/AWS D1.5 Qualification Type 5.12.1

– 5.12.2

– 5.12.4

Contractor/

Identification ___________________________________

Organization __________________________________

Revision _______ Date __________ By ____________

Welding Process(es) ____________________________

Authorized by __________________ Date __________

Type:

Manual

Semiautomatic

Supporting PQR No.(s) __________________________

Mechanized

Automatic

POSITION

Tandem

Parallel

Position of Groove ______________ Fillet __________

Vertical Progression: Up

Down

JOINT DESIGN USED

ELECTRICAL CHARACTERISTICS

Single

Double Weld

Transfer Mode (GMAW): Globular

Spray

Backing: Yes

No

Material _______________

Current: AC

DCEP

DCEN

Pulsed

Root Opening ______ Root Face Dimension ________

Electrical Stick Out ______________________________

Groove Angle ___________ Radius (J–U) _________

Other ________________________________________

Backgouging: Yes

No

Method ____________

Root Treatment ________________________________

TECHNIQUE

Stringer or Weave Bead __________________________

BASE METALS

Multi-pass or Single Pass (per side)_________________

Material Spec. _________________________________

Number of Electrodes ___________________________

Type or Grade _________________________________

Electrode Spacing: Longitudinal __________________

Thickness: Groove ____________ Fillet __________

Lateral _______________________ Angle__________

Diameter (Pipe) ________________________________

Interpass Cleaning ______________________________

PREHEAT

FILLER METALS

Preheat Temp., Min. _____________________________

AWS Specification______________________________

Interpass Temp., Min. ____________________________

AWS Classification _____________________________

Interpass Temp., Max. ___________________________

Manufacturer Trade Name________________________

POSTWELD HEAT TREATMENT

Temp. _________________ Hold Time_____________

SHIELDING

Heating/Cooling Rate ____________________________

Flux ___________________ Mfg. Trade Name_______

Electrode-Flux (Class)___________________________

HEAT INPUT

Gas Composition ______________________________

Calculated Heat Input Value: kJ/in

kJ/mm

Flow Rate ______________ Gas Cup Size _________

Max. Heat Input _________ Min. Heat Input_________

WELDING PROCEDURE

Filler

Metals

Current

Pass or

Weld

Type &

Amps or Wire

Travel

Layer(s)

Process

Diam.

Polarity

Feed Speed

Volts

Speed

Joint Details

Form N-2

Form N-2—Sample Welding Procedure Specification

269

1

1