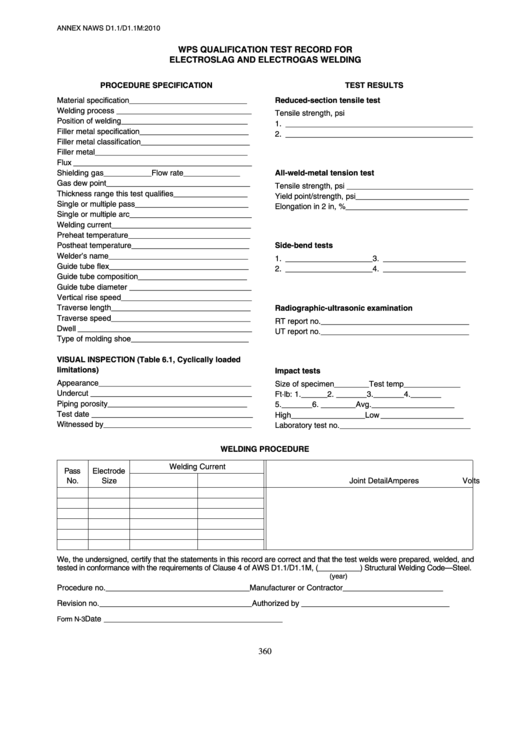

ANNEX N

AWS D1.1/D1.1M:2010

WPS QUALIFICATION TEST RECORD FOR

ELECTROSLAG AND ELECTROGAS WELDING

PROCEDURE SPECIFICATION

TEST RESULTS

Material specification ___________________________

Reduced-section tensile test

Welding process _______________________________

Tensile strength, psi

Position of welding _____________________________

1. ___________________________________________

Filler metal specification _________________________

2. ___________________________________________

Filler metal classification _________________________

Filler metal ___________________________________

Flux _________________________________________

Shielding gas ___________ Flow rate _____________

All-weld-metal tension test

Gas dew point _________________________________

Tensile strength, psi _____________________________

Thickness range this test qualifies _________________

Yield point/strength, psi __________________________

Single or multiple pass __________________________

Elongation in 2 in, % ____________________________

Single or multiple arc____________________________

Welding current ________________________________

Preheat temperature ____________________________

Postheat temperature ___________________________

Side-bend tests

Welder’s name ________________________________

1. ____________________ 3. ___________________

Guide tube flex ________________________________

2. ____________________ 4. ___________________

Guide tube composition _________________________

Guide tube diameter ____________________________

Vertical rise speed______________________________

Traverse length ________________________________

Radiographic-ultrasonic examination

Traverse speed ________________________________

RT report no. __________________________________

Dwell ________________________________________

UT report no. __________________________________

Type of molding shoe ___________________________

VISUAL INSPECTION (Table 6.1, Cyclically loaded

limitations)

Impact tests

Appearance___________________________________

Size of specimen ________ Test temp _____________

Undercut _____________________________________

Ft·lb: 1. ______

2. _______ 3. _______ 4. _______

Piping porosity ________________________________

5. _______

6. ________ Avg.___________________

Test date _____________________________________

High _________________ Low ___________________

Witnessed by__________________________________

Laboratory test no. ______________________________

WELDING PROCEDURE

Welding Current

Pass

Electrode

No.

Size

Amperes

Volts

Joint Detail

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in conformance with the requirements of Clause 4 of AWS D1.1/D1.1M, (__________ ) Structural Welding Code—Steel.

(year)

Procedure no. _________________________________

Manufacturer or Contractor _______________________

Revision no.___________________________________

Authorized by __________________________________

Date _________________________________________

Form N-3

360

1

1