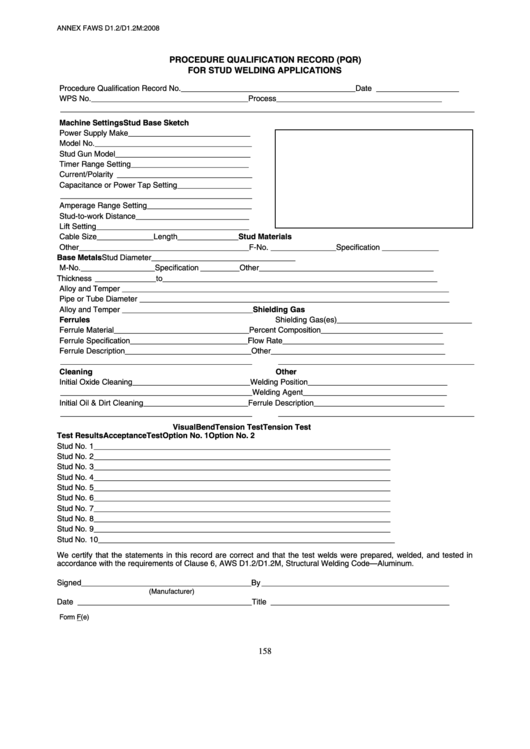

ANNEX F

AWS D1.2/D1.2M:2008

PROCEDURE QUALIFICATION RECORD (PQR)

FOR STUD WELDING APPLICATIONS

Procedure Qualification Record No.________________________________________

Date ___________________

WPS No. ____________________________________

Process ______________________________________

_______________________________________________________________________________________________

Machine Settings

Stud Base Sketch

Power Supply Make ____________________________

Model No.____________________________________

Stud Gun Model _______________________________

Timer Range Setting ___________________________

Current/Polarity _______________________________

Capacitance or Power Tap Setting _________________

____________________________________________

Amperage Range Setting________________________

Stud-to-work Distance __________________________

Lift Setting ___________________________________

Cable Size _____________

Length______________

Stud Materials

Other _______________________________________

F-No. _______________ Specification _____________

Base Metals

Stud Diameter _________________________________

M-No. _________________

Specification _________

Other ________________________________________

Thickness ______________

to__________________

_____________________________________________

Alloy and Temper ______________________________

_____________________________________________

Pipe or Tube Diameter __________________________

_____________________________________________

Alloy and Temper ______________________________

Shielding Gas

Ferrules

Shielding Gas(es)_______________________________

Ferrule Material _______________________________

Percent Composition ____________________________

Ferrule Specification ___________________________

Flow Rate _____________________________________

Ferrule Description_____________________________

Other ________________________________________

____________________________________________

_____________________________________________

Cleaning

Other

Initial Oxide Cleaning ___________________________

Welding Position________________________________

____________________________________________

Welding Agent _________________________________

Initial Oil & Dirt Cleaning ________________________

Ferrule Description______________________________

____________________________________________

_____________________________________________

Visual

Bend

Tension Test

Tension Test

Test Results

Acceptance

Test

Option No. 1

Option No. 2

Stud No. 1

_________________

_________________

_________________

_________________

Stud No. 2

_________________

_________________

_________________

_________________

Stud No. 3

_________________

_________________

_________________

_________________

Stud No. 4

_________________

_________________

_________________

_________________

Stud No. 5

_________________

_________________

_________________

_________________

Stud No. 6

_________________

_________________

_________________

_________________

Stud No. 7

_________________

_________________

_________________

_________________

Stud No. 8

_________________

_________________

_________________

_________________

Stud No. 9

_________________

_________________

_________________

_________________

Stud No. 10

_________________

_________________

_________________

_________________

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in

accordance with the requirements of Clause 6, AWS D1.2/D1.2M, Structural Welding Code—Aluminum.

Signed _______________________________________

By ___________________________________________

(Manufacturer)

Date ________________________________________

Title _________________________________________

Form F(e)

158

1

1