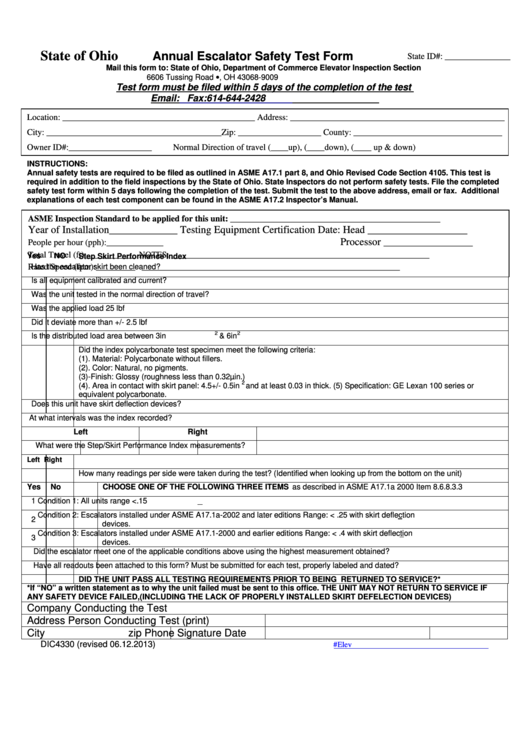

Annual Escalator Safety Test Form

ADVERTISEMENT

State of Ohio

Annual Escalator Safety Test Form

State ID#: _______________

Mail this form to: State of Ohio, Department of Commerce Elevator Inspection Section

6606 Tussing Road • P.O. Box 4009 Reynoldsburg, OH 43068-9009

Test form must be filed within 5 days of the completion of the test

Email:elevators@com.ohio.gov

Fax:614-644-2428

Location: ____________________________________________ Address: _________________________________________________

City: ________________________________________Zip: ___________________ County: __________________________________

Owner ID#:___________________

Normal Direction of travel (____up), (____down), (____ up & down)

INSTRUCTIONS:

Annual safety tests are required to be filed as outlined in ASME A17.1 part 8, and Ohio Revised Code Section 4105. This test is

required in addition to the field inspections by the State of Ohio. State Inspectors do not perform safety tests. File the completed

safety test form within 5 days following the completion of the test. Submit the test to the above address, email or fax. Additional

explanations of each test component can be found in the ASME A17.2 Inspector’s Manual.

ASME Inspection Standard to be applied for this unit: ________________________________________________

Year of Installation_____________ Testing Equipment Certification Date: Head ___________________

Processor _________________

People per hour (pph):_____________

Total Travel (ft):___________

NOTES: ___________________________________________________________

Yes

NO

Step Skirt Performance Index

Rated Speed (fpm):_________

Has the escalator skirt been cleaned?

___________________________________________________________

Is all equipment calibrated and current?

Was the unit tested in the normal direction of travel?

Was the applied load 25 lbf

Did it deviate more than +/- 2.5 lbf

2

2

Is the distributed load area between 3in

& 6in

Did the index polycarbonate test specimen meet the following criteria:

(1). Material: Polycarbonate without fillers.

(2). Color: Natural, no pigments.

(3)-Finish: Glossy (roughness less than 0.32µin.)

2

(4). Area in contact with skirt panel: 4.5+/- 0.5in

and at least 0.03 in thick. (5) Specification: GE Lexan 100 series or

equivalent polycarbonate.

Does this unit have skirt deflection devices?

At what intervals was the index recorded?

Left

Right

What were the Step/Skirt Performance Index measurements?

Left

Right

How many readings per side were taken during the test? (Identified when looking up from the bottom on the unit)

Yes

No

CHOOSE ONE OF THE FOLLOWING THREE ITEMS as described in ASME A17.1a 2000 Item 8.6.8.3.3

1

Condition 1: All units range <.15

Condition 2: Escalators installed under ASME A17.1a-2002 and later editions Range: < .25 with skirt deflection

2

devices.

Condition 3: Escalators installed under ASME A17.1-2000 and earlier editions Range: < .4 with skirt deflection

3

devices.

Did the escalator meet one of the applicable conditions above using the highest measurement obtained?

Have all readouts been attached to this form? Must be submitted for each test, properly labeled and dated?

DID THE UNIT PASS ALL TESTING REQUIREMENTS PRIOR TO BEING RETURNED TO SERVICE?*

*If “NO” a written statement as to why the unit failed must be sent to this office. THE UNIT MAY NOT RETURN TO SERVICE IF

ANY SAFETY DEVICE FAILED,(INCLUDING THE LACK OF PROPERLY INSTALLED SKIRT DEFELECTION DEVICES)

Company Conducting the Test

Address

Person Conducting Test

(print)

City

zip

Phone

Signature

Date

DIC4330 (revised 06.12.2013)

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Legal

1

1