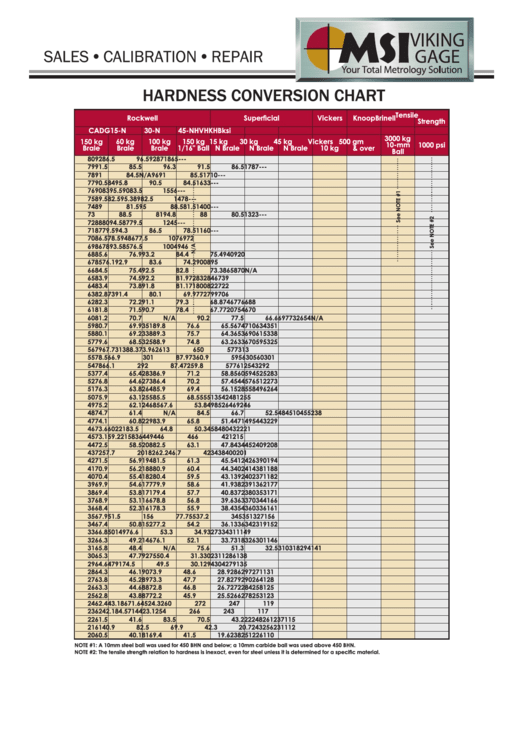

Hardness Conversion Chart

ADVERTISEMENT

SALES •CALIBRATION •REPAIR

HARDNESS CONVERSION CHART

Tensile

Rockwell

Superficial

Vickers

Knoop

Brinell

Strength

C

A

D

G

15-N

30-N

45-N

HV

HK

HB

ksi

3000 kg

150 kg

60 kg

100 kg

150 kg

15 kg

30 kg

45 kg

Vickers

500 gm

10-mm

1000 psi

Brale

Brale

Brale

1/16" Ball

N Brale

N Brale

N Brale

10 kg

& over

Ball

80

92

86.5

96.5

92

87

1865

---

79

91.5

85.5

96.3

91.5

86.5

1787

---

78

91

84.5

N/A

96

91

85.5

1710

---

77

90.5

84

95.8

90.5

84.5

1633

---

76

90

83

95.5

90

83.5

1556

---

75

89.5

82.5

95.3

89

82.5

1478

---

74

89

81.5

95

88.5

81.5

1400

---

73

88.5

81

94.8

88

80.5

1323

---

72

88

80

94.5

87

79.5

1245

---

71

87

79.5

94.3

86.5

78.5

1160

---

70

86.5

78.5

94

86

77.5

1076

972

69

86

78

93.5

85

76.5

1004

946

68

85.6

76.9

93.2

84.4

75.4

940

920

67

85

76.1

92.9

83.6

74.2

900

895

66

84.5

75.4

92.5

82.8

73.3

865

870

N/A

65

83.9

74.5

92.2

81.9

72

832

846

739

64

83.4

73.8

91.8

81.1

71

800

822

722

63

82.8

73

91.4

80.1

69.9

772

799

706

62

82.3

72.2

91.1

79.3

68.8

746

776

688

61

81.8

71.5

90.7

78.4

67.7

720

754

670

60

81.2

70.7

N/A

90.2

77.5

66.6

697

732

654

N/A

59

80.7

69.9

351

89.8

76.6

65.5

674

710

634

351

58

80.1

69.2

338

89.3

75.7

64.3

653

690

615

338

57

79.6

68.5

325

88.9

74.8

63.2

633

670

595

325

56

79

67.7

313

88.3

73.9

62

613

650

577

313

55

78.5

66.9

301

87.9

73

60.9

595

630

560

301

54

78

66.1

292

87.4

72

59.8

577

612

543

292

53

77.4

65.4

283

86.9

71.2

58.8

560

594

525

283

52

76.8

64.6

273

86.4

70.2

57.4

544

576

512

273

51

76.3

63.8

264

85.9

69.4

56.1

528

558

496

264

50

75.9

63.1

255

85.5

68.5

55

513

542

481

255

49

75.2

62.1

246

85

67.6

53.8

498

526

469

246

48

74.7

61.4

N/A

84.5

66.7

52.5

484

510

455

238

47

74.1

60.8

229

83.9

65.8

51.4

471

495

443

229

46

73.6

60

221

83.5

64.8

50.3

458

480

432

221

45

73.1

59.2

215

83

64

49

446

466

421

215

44

72.5

58.5

208

82.5

63.1

47.8

434

452

409

208

43

72

57.7

201

82

62.2

46.7

423

438

400

201

42

71.5

56.9

194

81.5

61.3

45.5

412

426

390

194

41

70.9

56.2

188

80.9

60.4

44.3

402

414

381

188

40

70.4

55.4

182

80.4

59.5

43.1

392

402

371

182

39

69.9

54.6

177

79.9

58.6

41.9

382

391

362

177

38

69.4

53.8

171

79.4

57.7

40.8

372

380

353

171

37

68.9

53.1

166

78.8

56.8

39.6

363

370

344

166

36

68.4

52.3

161

78.3

55.9

38.4

354

360

336

161

35

67.9

51.5

156

77.7

55

37.2

345

351

327

156

34

67.4

50.8

152

77.2

54.2

36.1

336

342

319

152

33

66.8

50

149

76.6

53.3

34.9

327

334

311

149

32

66.3

49.2

146

76.1

52.1

33.7

318

326

301

146

31

65.8

48.4

N/A

75.6

51.3

32.5

310

318

294

141

30

65.3

47.7

92

75

50.4

31.3

302

311

286

138

29

64.6

47

91

74.5

49.5

30.1

294

304

279

135

28

64.3

46.1

90

73.9

48.6

28.9

286

297

271

131

27

63.8

45.2

89

73.3

47.7

27.8

279

290

264

128

26

63.3

44.6

88

72.8

46.8

26.7

272

284

258

125

25

62.8

43.8

87

72.2

45.9

25.5

266

278

253

123

24

62.4

43.1

86

71.6

45

24.3

260

272

247

119

23

62

42.1

84.5

71

44

23.1

254

266

243

117

22

61.5

41.6

83.5

70.5

43.2

22

248

261

237

115

21

61

40.9

82.5

69.9

42.3

20.7

243

256

231

112

20

60.5

40.1

81

69.4

41.5

19.6

238

251

226

110

NOTE #1: A 10mm steel ball was used for 450 BHN and below; a 10mm carbide ball was used above 450 BHN.

NOTE #2: The tensile strength relation to hardness is inexact, even for steel unless it is determined for a specific material.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1