Da Form 5687-R - Initial Inspection Checklist For Indoor Ranges Page 2

ADVERTISEMENT

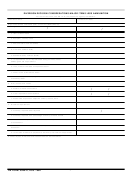

DETAILED INSPECTION CHECKLIST FOR INDOOR RANGES

For use of this form. see HQDA LTR 385-91-1; the proponent agency is OCSA

SECTION I - BUILDING ENVELOPE

YES

NO

REMARKS

1.

Width of firing lanes is adequate (a minimum of 4 feet to fire rifle and/or pistol).

(Noncritical but may present some operational problems particularly when firing in

the prone position.)

2.

Single steel plate bullet stop with sand type trap (plate/sand trap) set at an angle of

45° (+ or -5°) from the vertical and inclined forward towards the firing line. (Critical

only if it appears backsplatter of lead particles occurs all the way back to the firing

line.) (.22 Caliber firing (std))

3.

Escalator bullet stop is set at an angle of 30° from the horizontal. (Criticality as

discussed in para 2 above.) (M16 firing)

4.

Thickness of steel plate/sand trap type bullet stop is adequate to attenuate the

maximum caliber of ammunition authorized to be fired on the range. (Critical only if

bullet stop is damaged to the point where repair/replacement is necessary.

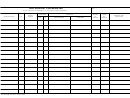

DIMENSIONS OF ARMOR BACKSTOPS. SIDE PLATES AND BAFFLING PLATES

Caliber

Thickness of

Thickness of

Thickness of

(up to)

Backstops

Side Plates

Steelplate in

(minimum)

(minimum)

Baffling

.22 S/LR

1/4" @ 45°

3/16"

3/16" @ 30°

.38 wadcutter

3/8" @ 45°

1/4"

1/4" @ 30°

.45

1/2" @ 45°

3/8"

3/8" @ 30°

5.56mm (M193)

5/8" steel plate

3/8"

3/8" @ 30°

w/8" reinforced

concrete

5.56mm (M855)

1" hardened steel

armor plate 1"

armor plate

plate permanently

@ 30°

affixed to backstop

w/1" armor plate facing

5.

Plate/sand trap type bullet stop is property installed and joints and edge lines

backed with a continuous 1/4", thick steel backing plate 4 inches in width or wider.

(Critical if missing and joints and edge lines show signs of bullet damage.)

6.

Plate/sand trap bullet stop is suspended by angle braces faced with wood to

prevent ricochet or backsplatter. (Critical only if braces show signs of bullet

damage.)

7.

Bullet stop sidewalls are of steel or covered with steel plate. (Critical only it there is

evidence of plate being punctured by bullets.)

8.

Plate/sand trap type sideplates extend vertically downward from the top edge of the

bullet stop to the bottom of the sandpit to the bottom rear age of the bullet stop.

(Critical to protect building and adjacent areas.)

9.

Sideplates extend vertically downward from the top edge of the bullet stop to the

bottom rear edge of the bullet stop. (Critical to protect building and adjacent areas.)

10. In high ceiling buildings where the plate/sand trap type of bullet stop has been

installed, the rear wall above the stop is lined with 2" of wood (or 2 sheets of 3/4"

plywood over a 1/8" steel plate to prevent shooting through the rear wall).

11. Pitted or bowed steel bullet stop plates are repaired by cutting out the damaged

piece and welding in a new piece. (Critical to the extent that this condition may

result in ricochet, backsplatter, or damage to the building walls.)

12. Welds are ground smooth to prevent backsplatter. (Self-explanatory, also should

prolong life of the weld.)

13. Forward leading edges in a louvre or venetian-blind type of bullet stop are

maintained "knife-sharp" to prevent ricochet. (Critical where leading edges are

blunted and cause ricochets or backsplatter.)

DA FORM 5688-R, DEC 90

DA FORM 5687-R. APR 88 IS OBSOLETE

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5