Aircraft Accident Brief Ntsb/aab-02/01 (Pb2002-910401): Egypt Air Flight 990, Boeing 767-366er, Su-Gap - National Transportation Safety Board Page 125

ADVERTISEMENT

1

1  2

2  3

3  4

4  5

5  6

6  7

7  8

8  9

9  10

10  11

11  12

12  13

13  14

14  15

15  16

16  17

17  18

18  19

19  20

20  21

21  22

22  23

23  24

24  25

25  26

26  27

27  28

28  29

29  30

30  31

31  32

32  33

33  34

34  35

35  36

36  37

37  38

38  39

39  40

40  41

41  42

42  43

43  44

44  45

45  46

46  47

47  48

48  49

49  50

50  51

51  52

52  53

53  54

54  55

55  56

56  57

57  58

58  59

59  60

60  61

61  62

62  63

63  64

64  65

65  66

66  67

67  68

68  69

69  70

70  71

71  72

72  73

73  74

74  75

75  76

76  77

77  78

78  79

79  80

80  81

81  82

82  83

83  84

84  85

85  86

86  87

87  88

88  89

89  90

90  91

91  92

92  93

93  94

94  95

95  96

96  97

97  98

98  99

99  100

100  101

101  102

102  103

103  104

104  105

105  106

106  107

107  108

108  109

109  110

110  111

111  112

112  113

113  114

114  115

115  116

116  117

117  118

118  119

119  120

120  121

121  122

122  123

123  124

124  125

125  126

126  127

127  128

128  129

129  130

130  131

131  132

132  133

133  134

134  135

135  136

136  137

137  138

138  139

139  140

140  141

141  142

142  143

143  144

144  145

145  146

146  147

147  148

148  149

149  150

150  151

151  152

152  153

153  154

154  155

155  156

156  157

157  158

158  159

159  160

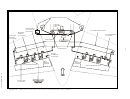

160 The Egyptian Team attempted to have the bellcrank issue thoroughly investigated by the

NTSB Systems Group. Failing in this effort, the Egyptian Team took the unusual step of

preparing a safety recommendation letter from the Director General of the ECAA directly to the

FAA Administrator. The letter described the factual findings and the safety problems that had

been identified in the EgyptAir 990 accident investigation. The three recommendations, sent to

the FAA on June 4, 2000, stated:

1.

Require a cockpit indication in the Boeing 767 that would alert the flight crew to

abnormal PCA operation wherein a single fault in the elevator could result in

uncommanded elevator movement. Until such a cockpit indicator is installed,

require operators of Boeing 767 airplanes to perform daily -- rather than 400-hour

-- checks of the elevator system to identify faults in the elevator system;

2.

Review the Boeing 767 elevator control system design and conduct further

examination of the causes of the reported discrepancies found in the elevator

actuator bellcrank, and;

3.

In conjunction with Boeing, develop cockpit crew procedures to aid the flight

crew in identifying, isolating, and negating an uncommanded elevator hard-over

condition.

These safety issue recommendations prompted action by the FAA which requested that

Boeing undertake specific tests on the Boeing 767 elevator control system. The NTSB did not

participate in this testing even though the issues arose from the Flight 990 accident investigation

and appeared to be relevant to the accident. In any event, the identification and resolution of

these safety issues should have come through the NTSB to the FAA.

The tests initiated by the FAA resulted in dramatic safety findings. In a July 20, 2000,

Boeing message to all operators, Boeing stated that the test “ . . . results revealed that the

Elevator Power Control Actuator, Maintenance Planning Document Item Number 27-31-00-5B

test, which is required at a 400-hour interval, may not detect a failed hydraulic.” As a result, “. .

. the single system hydraulic test passed even though there was a sheared bellcrank in one

8

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Legal