Chemical Resistance Chart - Liquiflo

ADVERTISEMENT

E N G I N E E R I N G - C h e m i c a l D a t a

TM

CHEMICAL RESISTANCE CHART

factors, which can cause chemical ratings

Notice: The Chemical Resistance Chart

to change within a given application.

given on the following pages is intended

Such factors include variations in

as a general guide for rating the resistance

temperature, pressure and concentration,

of typical engineering materials to

chemical combinations, impurities or filler

common industrial chemicals. It is not

materials, aeration, agitation and exposure

intended as a guarantee of material

time. It is recommended that pumps and

performance. The ratings in the chart are

materials first be tested under simulated

based on data obtained from technical

field service conditions. Never test or

publications, material manufacturers and

operate a pump before acceptable

laboratory tests. The information given in

chemical ratings have been obtained

the chart should be used as a first

and the proper safety precautions have

approximation for material selection,

been taken .

rather than the final answer. This is because

chemical effects are dependent on many

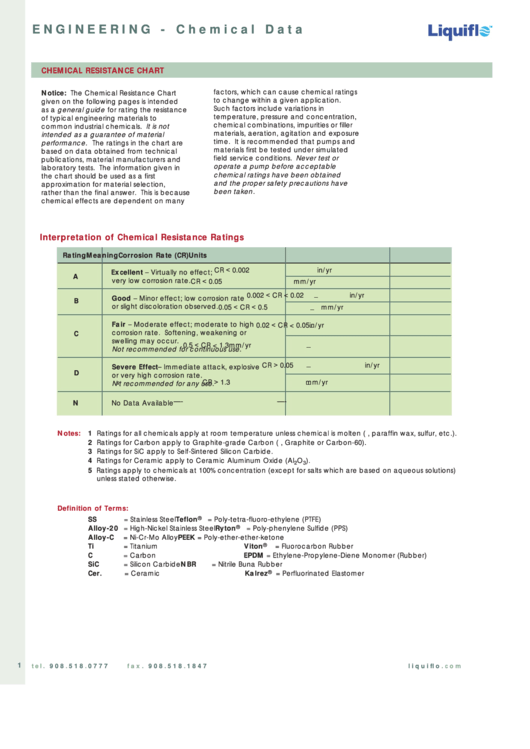

Interpretation of Chemical Resistance Ratings

Rating

Meaning

Corrosion Rate (CR)

Units

CR < 0.002

in/yr

Excellent – Virtually no effect;

very low corrosion rate.

CR < 0.05

mm/yr

A

0.002 < CR < 0.02

in/yr

Good – Minor effect; low corrosion rate

or slight discoloration observed.

0.05 < CR < 0.5

mm/yr

B

Fair – Moderate effect; moderate to high

0.02 < CR < 0.05

in/yr

corrosion rate. Softening, weakening or

swelling may occur.

C

0.5 < CR < 1.3

mm/yr

Not recommended for continuous use.

CR > 0.05

in/yr

Severe Effect – Immediate attack, explosive

or very high corrosion rate.

D

CR > 1.3

mm/yr

Not recommended for any use.

—-

—-

No Data Available

N

1 Ratings for all chemicals apply at room temperature unless chemical is molten (e.g., paraffin wax, sulfur, etc.).

Notes:

2 Ratings for Carbon apply to Graphite-grade Carbon (i.e., Graphite or Carbon-60).

3 Ratings for SiC apply to Self-Sintered Silicon Carbide.

4 Ratings for Ceramic apply to Ceramic Aluminum Oxide (Al

O

).

2

3

5 Ratings apply to chemicals at 100% concentration (except for salts which are based on aqueous solutions)

unless stated otherwise.

Definition of Terms:

= Stainless Steel

= Poly-tetra-fluoro-ethylene (PTFE)

®

SS

Teflon

Alloy-20 = High-Nickel Stainless Steel

= Poly-phenylene Sulfide (PPS)

®

Ryton

= Ni-Cr-Mo Alloy

= Poly-ether-ether-ketone

Alloy-C

PEEK

= Titanium

= Fluorocarbon Rubber

®

Ti

Viton

= Carbon

= Ethylene-Propylene-Diene Monomer (Rubber)

C

EPDM

= Silicon Carbide

= Nitrile Buna Rubber

SiC

NBR

= Ceramic

= Perfluorinated Elastomer

®

Cer.

Kalrez

1

t e l .

9 0 8

.

5 1 8

.

0 7 7 7

f a x .

9 0 8

.

5 1 8

.

1 8 4 7

w w w .

l i q u i f l o

. c o m

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4