Metal Extraction

ADVERTISEMENT

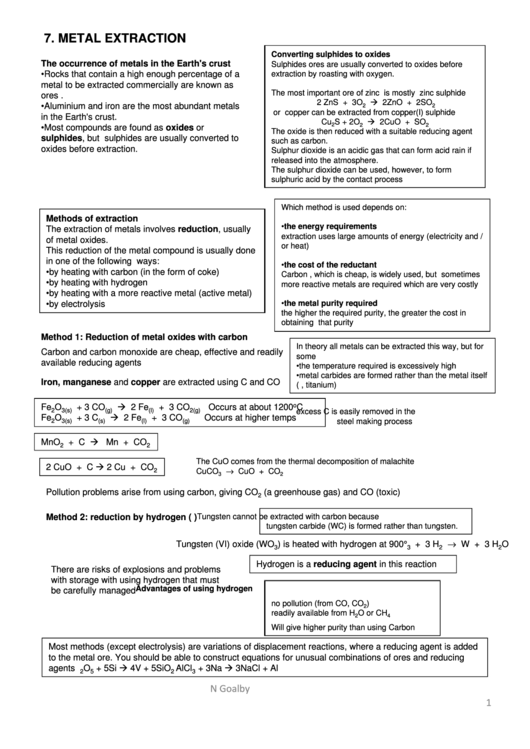

7. METAL EXTRACTION

Converting sulphides to oxides

The occurrence of metals in the Earth's crust

Sulphides ores are usually converted to oxides before

•Rocks that contain a high enough percentage of a

extraction by roasting with oxygen.

metal to be extracted commercially are known as

The most important ore of zinc is mostly zinc sulphide

ores .

2 ZnS + 3O

2ZnO + 2SO

•Aluminium and iron are the most abundant metals

2

2

or copper can be extracted from copper(I) sulphide

in the Earth's crust.

Cu

S + 2O

2CuO + SO

2

2

2

•Most compounds are found as oxides or

The oxide is then reduced with a suitable reducing agent

sulphides, but sulphides are usually converted to

such as carbon.

oxides before extraction.

Sulphur dioxide is an acidic gas that can form acid rain if

released into the atmosphere.

The sulphur dioxide can be used, however, to form

sulphuric acid by the contact process

Which method is used depends on:

Methods of extraction

•the energy requirements

The extraction of metals involves reduction, usually

extraction uses large amounts of energy (electricity and /

of metal oxides.

or heat)

This reduction of the metal compound is usually done

in one of the following ways:

•the cost of the reductant

•by heating with carbon (in the form of coke)

Carbon , which is cheap, is widely used, but sometimes

•by heating with hydrogen

more reactive metals are required which are very costly

•by heating with a more reactive metal (active metal)

•the metal purity required

•by electrolysis

the higher the required purity, the greater the cost in

obtaining that purity

Method 1: Reduction of metal oxides with carbon

In theory all metals can be extracted this way, but for

Carbon and carbon monoxide are cheap, effective and readily

some

available reducing agents

•the temperature required is excessively high

•metal carbides are formed rather than the metal itself

Iron, manganese and copper are extracted using C and CO

(e.g. tungsten, titanium)

o

Fe

O

+ 3 CO

2 Fe

+ 3 CO

Occurs at about 1200

C

2

3(s)

(g)

(l)

2(g)

excess C is easily removed in the

Fe

O

+ 3 C

2 Fe

+ 3 CO

Occurs at higher temps

steel making process

2

3(s)

(s)

(l)

(g)

MnO

+ C

Mn + CO

2

2

The CuO comes from the thermal decomposition of malachite

2 CuO + C

2 Cu + CO

→ CuO + CO

2

CuCO

3

2

Pollution problems arise from using carbon, giving CO

(a greenhouse gas) and CO (toxic)

2

Tungsten cannot be extracted with carbon because

Method 2: reduction by hydrogen (e.g. W)

tungsten carbide (WC) is formed rather than tungsten.

→ W + 3 H

WO

+ 3 H

O

Tungsten (VI) oxide (WO

) is heated with hydrogen at 900°C.

3

2

2

3

Hydrogen is a reducing agent in this reaction

There are risks of explosions and problems

with storage with using hydrogen that must

Advantages of using hydrogen

be carefully managed

no pollution (from CO, CO

)

2

readily available from H

O or CH

2

4

Will give higher purity than using Carbon

Most methods (except electrolysis) are variations of displacement reactions, where a reducing agent is added

to the metal ore. You should be able to construct equations for unusual combinations of ores and reducing

agents e.g. 2V

O

+ 5Si

4V + 5SiO

AlCl

+ 3Na

3NaCl + Al

2

5

2

3

N Goalby

1

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Education

1

1 2

2