Cost Effectiveness For Low Nox Burner

ADVERTISEMENT

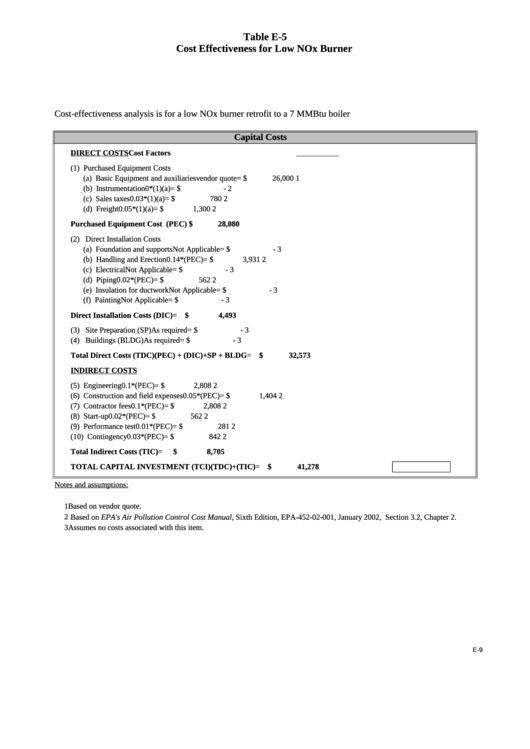

Table E-5

Cost Effectiveness for Low NOx Burner

Cost-effectiveness analysis is for a low NOx burner retrofit to a 7 MMBtu boiler

Capital Costs

DIRECT COSTS

Cost Factors

(1) Purchased Equipment Costs

(a) Basic Equipment and auxiliaries

vendor quote

= $

26,000 1

(b) Instrumentation

0 * (1)(a)

=

$

- 2

(c) Sales taxes

0.03 * (1)(a)

= $

780 2

(d) Freight

0.05 * (1)(a)

= $

1,300 2

Purchased Equipment Cost (PEC)

$

28,080

(2) Direct Installation Costs

(a) Foundation and supports

Not Applicable

=

$

- 3

(b) Handling and Erection

0.14 * (PEC)

= $

3,931 2

(c) Electrical

Not Applicable

=

$

- 3

(d) Piping

0.02 * (PEC)

= $

562 2

(e) Insulation for ductwork

Not Applicable

=

$

- 3

(f) Painting

Not Applicable

=

$

- 3

Direct Installation Costs (DIC)

= $

4,493

(3) Site Preparation (SP)

As required

=

$

- 3

(4) Buildings (BLDG)

As required

=

$

- 3

Total Direct Costs (TDC)

(PEC) + (DIC) + SP + BLDG

= $

32,573

INDIRECT COSTS

(5) Engineering

0.1 * (PEC)

= $

2,808 2

(6) Construction and field expenses

0.05 * (PEC)

= $

1,404 2

(7) Contractor fees

0.1 * (PEC)

= $

2,808 2

(8) Start-up

0.02 * (PEC)

= $

562 2

(9) Performance test

0.01 * (PEC)

= $

281 2

(10) Contingency

0.03 * (PEC)

= $

842 2

Total Indirect Costs (TIC)

=

$

8,705

TOTAL CAPITAL INVESTMENT (TCI)

(TDC) + (TIC)

= $

41,278

Notes and assumptions:

1 Based on vendor quote.

2

Based on EPA's Air Pollution Control Cost Manual, Sixth Edition, EPA-452-02-001, January 2002, Section 3.2, Chapter 2.

3 Assumes no costs associated with this item.

E-9

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2