Drill Press Speed Chart

ADVERTISEMENT

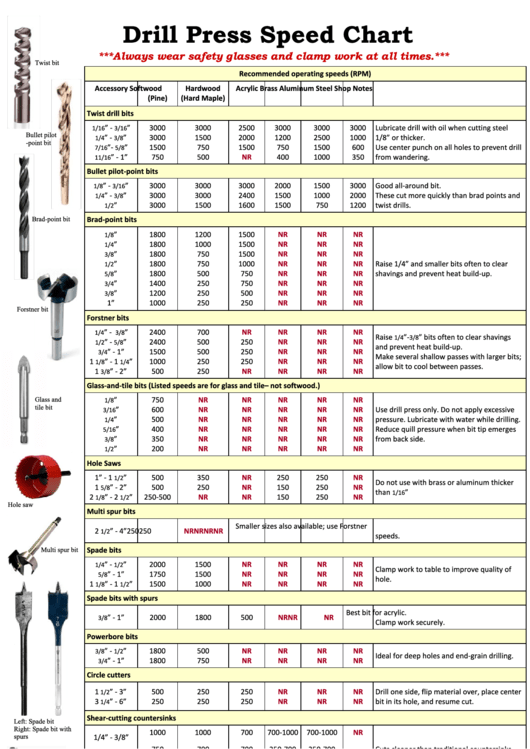

Drill Press Speed Chart

***Always wear safety glasses and clamp work at all times.***

Twist bit

Recommended operating speeds (RPM)

Accessory

Softwood

Hardwood

Acrylic

Brass

Aluminum

Steel

Shop Notes

(Pine)

(Hard Maple)

Twist drill bits

” -

”

3000

3000

2500

3000

3000

3000

Lubricate drill with oil when cutting steel

1/16

3/16

Bullet pilot

” -

”

3000

1500

2000

1200

2500

1000

1/8” or thicker.

1/4

3/8

-point bit

”-

”

1500

750

1500

750

1500

600

Use center punch on all holes to prevent drill

7/16

5/8

” - 1”

750

500

NR

400

1000

350

from wandering.

11/16

Bullet pilot-point bits

” -

”

3000

3000

3000

2000

1500

3000

Good all-around bit.

1/8

3/16

” -

”

3000

3000

2400

1500

1000

2000

These cut more quickly than brad points and

1/4

3/8

”

3000

1500

1600

1500

750

1200

twist drills.

1/2

Brad-point bit

Brad-point bits

”

1800

1200

1500

NR

NR

NR

1/8

”

1800

1000

1500

NR

NR

NR

1/4

”

1800

750

1500

NR

NR

NR

3/8

”

1800

750

1000

NR

NR

NR

Raise 1/4” and smaller bits often to clear

1/2

”

1800

500

750

NR

NR

NR

shavings and prevent heat build-up.

5/8

”

1400

250

750

NR

NR

NR

3/4

”

1200

250

500

NR

NR

NR

3/8

1”

1000

250

250

NR

NR

NR

Forstner bit

Forstner bits

” -

”

2400

700

NR

NR

NR

NR

1/4

3/8

Raise

”-

” bits often to clear shavings

1/4

3/8

” -

”

2400

500

250

NR

NR

NR

1/2

5/8

and prevent heat build-up.

” - 1”

1500

500

250

NR

NR

NR

3/4

Make several shallow passes with larger bits;

1

” - 1

”

1000

250

250

NR

NR

NR

1/8

1/4

allow bit to cool between passes.

1

” - 2”

500

250

NR

NR

NR

NR

3/8

Glass-and-tile bits (Listed speeds are for glass and tile– not softwood.)

Glass and

”

750

NR

NR

NR

NR

NR

1/8

tile bit

”

600

NR

NR

NR

NR

NR

Use drill press only. Do not apply excessive

3/16

”

500

NR

NR

NR

NR

NR

pressure. Lubricate with water while drilling.

1/4

”

400

NR

NR

NR

NR

NR

Reduce quill pressure when bit tip emerges

5/16

”

350

NR

NR

NR

NR

NR

from back side.

3/8

”

200

NR

NR

NR

NR

NR

1/2

Hole Saws

1” - 1

”

500

350

NR

250

250

NR

1/2

Do not use with brass or aluminum thicker

1

” - 2”

500

250

NR

150

250

NR

5/8

than

”

1/16

2

” - 2

”

250-500

NR

NR

150

250

NR

1/8

1/2

Hole saw

Multi spur bits

Smaller sizes also available; use Forstner

2

” - 4”

250

250

NR

NR

NR

NR

1/2

speeds.

Multi spur bit

Spade bits

” -

”

2000

1500

NR

NR

NR

NR

1/4

1/2

Clamp work to table to improve quality of

” - 1”

1750

1500

NR

NR

NR

NR

5/8

hole.

1

” - 1

”

1500

1000

NR

NR

NR

NR

1/8

1/2

Spade bits with spurs

Best bit for acrylic.

” - 1”

2000

1800

500

NR

NR

NR

3/8

Clamp work securely.

Powerbore bits

” -

”

1800

500

NR

NR

NR

NR

3/8

1/2

Ideal for deep holes and end-grain drilling.

” - 1”

1800

750

NR

NR

NR

NR

3/4

Circle cutters

1

” - 3”

500

250

250

NR

NR

NR

Drill one side, flip material over, place center

1/2

3

” - 6”

250

250

250

NR

NR

NR

bit in its hole, and resume cut.

1/4

Shear-cutting countersinks

Left: Spade bit

Right: Spade bit with

1000

1000

700

700-1000

700-1000

NR

spurs

1/4” - 3/8”

Cuts cleaner than traditional countersinks.

750

700

700

250-700

250-700

NR

Countersinks

Powerbore bit

2-flute

1400

1400

NR

NR

NR

NR

Raise and lower frequently for quicker cut-

5-flute

1000

750

750

250

250

250

ting.

Countersink screw pilot bits

All sizes

1500

1000

500

500

NR

NR

Clear twist drill often.

Taper drill bits with countersinks

All sizes

500

250

250

NR

NR

NR

Clear bit often to prevent heat build-up.

Plug cutters

All sizes

1000

500

NR

NR

NR

NR

Cut to full depth so bit chamfers plug.

NR—not recommended

NOTES

Circle cutter

Recommendations are based on visual and tactile tests under shop conditions. Drilling faster than recommended can cause over-

heating. Speeds slower than recommended may cause poor-quality holes.

All wood testing done on face grain. Reduce speed when drilling into end grain.

Speeds based on new bits from the factory.

Shear-cutting countersink

Countersink

Countersink screw pilot bit

Taper bit w/ countersink

Plug cutter

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1