Samples Job Safety Analysis Page 23

ADVERTISEMENT

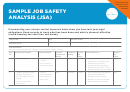

SAMPLE JOB SAFETY ANALYSIS

MACHINE OPERATOR

1 of 2

103

x

Date:

:

Job Title

Page:

JSA No.

New

7-7-00

Revised

Equipment: CINCINNATI PRESS BRAKE

James Smith

Supervisor:

James Smith and Louis Andres, Operator

Analysis by:

Department: METAL FORMING

Rhonda Ames

Approved by:

Heavy gloves, Kevlar sleeves, safety glasses w/side shields, heavy work boot (steel toe optional).

Required Personal Protective Equipment (PPE):

JOB STEPS

POTENTIAL HAZARDS

RECOMMENDED

SAFE JOB PROCEDURES

1. Turn on press brake

Parts: tools, debris, electric shock

Good housekeeping; check area is clear of tools, parts, debris.

Inside/outside press brake, floor area

Check flex cords for damage and exposed wiring. Wear PPE.

Flying pieces/slip, trip, fall

2. Test 2-hand controls

Point of operation

Check operating selector - single stroke. Test controls-

Crush or amputate

concurrent, anti-tie-down, anti-repeat, no bridging, protected

Finger, hand

from accidental activation. Test stop control.

3. Receive parts

Moving Hilo and stationary parts

Move out of way while Hilo is delivering parts so body is not in

Struck by or crushed between Hilo and

pinch point.

Press brake or table

4. Cut banding

Sharp edges and release of coiled energy

Use proper cutting tool.

Lacerations

Hands, arms, face, eyes

5. Discard banding

Sharp edges and long, loose banding

Wind up banding and deposit into-drum. Observe for tripping

Lacerations/trip, fall

on loose bands.

Hands, arms, face, eyes

6. Remove blank from stack

Sharp edges

Grasp along edges. Pull blank toward you.

Lacerations, cuts

Hands, fingers

Page 17

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27