Viessmann Commercial Project Sign-Off Forms Set Page 8

ADVERTISEMENT

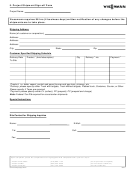

Check Here

VSB/

Necessary Conditions for Start-up

VD2

CT3

Ensure all boiler enclosure panels are installed.

Ensure burner is mounted onto combustion chamber door.

Ensure supply/return header, including all shunt pump(s) and mixing valves (where

N/A

required), is piped to system.

Ensure low water cutoff installed at high point on boiler or in piping above pressure

vessel.

IMPORTANT: Ensure heating system and boiler(s) are filled and a full heating load

exists for start-up; expansion tank must be installed.

Ensure power supply to boiler is installed.

Supply photo

On 575/120-volt burners, ensure a transformer is installed (field supplied) according

to diagram supplied with controls.

Ensure low water cut-off is wired.

Ensure outdoor temperature sensor is installed (if applicable).

Ensure the #5 sensor is installed in tank well and wired to boiler control where DHW

tanks are used.

Ensure control is mounted on boiler and electrically connected.

When Viessmann control panel is supplied for project, control panel must be wall

mounted, supplied with the specified power, and all pumps controlled by panel must

be properly wired.

Ensure gas train is purged of air, and pressure tested; gas meter must be accessible

and operational.

Ensure gas piping to burner gas train is installed with appropriate unions allowing

service to burner/boiler.

Ensure gas train regulator vents are piped to the outside or to a vent-limiting orifice

pending gas code or local regulations.

NG/LP applications: ensure gas train wired to burner.

Gas installation supply photo

Ensure gas pressure specified on Form 1 is available.

Oil applications: ensure filters/pumps installed.

Oil installation supply photo

.

Vent connected to boiler according to installation instructions

Supply photo

Ensure barometric damper is installed in venting.

N/A

Ensure ‘P’ traps are installed on condensate drains and condensate piping is routed

N/A

to a floor drain.

Ensure proper size combustion air and ventilation air openings are provided to boiler

room.

If a motorized damper has been installed to open the supply of the combustion air

and ventilation to the mechanical room, has the "full open proving switch" on the

damper been interlocked with the activation of the burner?

Ensure combustion air is free of any chemical contaminants.

Where combustion air is ducted to burner, ensure proper size insulated duct

complete with all connection flanges and intake screened terminal is installed.

IMPORTANT

Each of the “Necessary Conditions for Start-up” must be met prior to the start-up

technicians arriving. Failure to meet these conditions may incur costs additional

to those originally quoted.

Upon completion, please fax completed Cover Page together with completed Forms (some or all) to:

- Viessmann Canada:

(519) 885-1134

(for all provinces except BC)

- Viessmann BC:

(604) 533-9439

(for west coast Customers)

- Viessmann USA:

(401) 732-0590

(for US Customers)

Commercial Project Sign off Form

12/2010

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8