Unified (Inch) And Metric Thread Sizes - Advance Components

ADVERTISEMENT

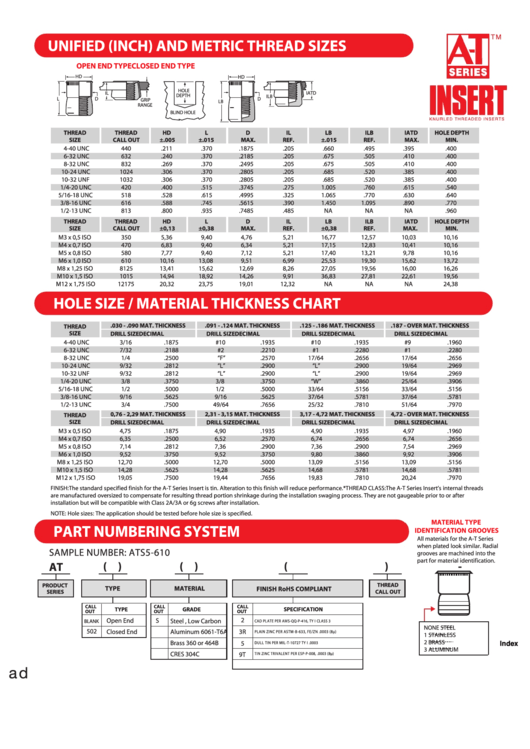

UNIFIED (INCH) AND METRIC THREAD SIZES

OPEN END TYPE

CLOSED END TYPE

HD

HD

HOLE

IATD

IL

DEPTH

ILB

L

D

D

GRIP

LB

RANGE

BLIND HOLE

THREAD

THREAD

HD

L

D

IL

LB

ILB

IATD

HOLE DEPTH

SIZE

CALL OUT

±.005

±.015

MAX.

REF.

±.015

REF.

MAX.

MIN.

4-40 UNC

440

.211

.370

.1875

.205

.660

.495

.395

.400

6-32 UNC

632

.240

.370

.2185

.205

.675

.505

.410

.400

8-32 UNC

832

.269

.370

.2495

.205

.675

.505

.410

.400

10-24 UNC

1024

.306

.370

.2805

.205

.685

.520

.385

.400

10-32 UNF

1032

.306

.370

.2805

.205

.685

.520

.385

.400

1/4-20 UNC

420

.400

.515

.3745

.275

1.005

.760

.615

.540

5/16-18 UNC

518

.528

.615

.4995

.325

1.065

.770

.630

.640

3/8-16 UNC

616

.588

.745

.5615

.390

1.450

1.095

.890

.770

1/2-13 UNC

813

.800

.935

.7485

.485

NA

NA

NA

.960

THREAD

THREAD

HD

L

D

IL

LB

ILB

IATD

HOLE DEPTH

SIZE

CALL OUT

±0,13

±0,38

MAX.

REF.

±0,38

REF.

MAX.

MIN.

M3 x 0,5 ISO

350

5,36

9,40

4,76

5,21

16,77

12,57

10,03

10,16

M4 x 0,7 ISO

470

6,83

9,40

6,34

5,21

17,15

12,83

10,41

10,16

M5 x 0,8 ISO

580

7,77

9,40

7,12

5,21

17,40

13,21

9,78

10,16

M6 x 1,0 ISO

610

10,16

13,08

9,51

6,99

25,53

19,30

15,62

13,72

M8 x 1,25 ISO

8125

13,41

15,62

12,69

8,26

27,05

19,56

16,00

16,26

M10 x 1,5 ISO

1015

14,94

18,92

14,26

9,91

36,83

27,81

22,61

19,56

M12 x 1,75 ISO

12175

20,32

23,75

19,01

12,32

NA

NA

NA

24,38

HOLE SIZE / MATERIAL THICKNESS CHART

.030 - .090 MAT. THICKNESS

.091 - .124 MAT. THICKNESS

.125 - .186 MAT. THICKNESS

.187 - OVER MAT. THICKNESS

THREAD

SIZE

DRILL SIZE

DECIMAL

DRILL SIZE

DECIMAL

DRILL SIZE

DECIMAL

DRILL SIZE

DECIMAL

4-40 UNC

3/16

.1875

#10

.1935

#10

.1935

#9

.1960

6-32 UNC

7/32

.2188

#2

.2210

#1

.2280

#1

.2280

8-32 UNC

1/4

.2500

“F”

.2570

17/64

.2656

17/64

.2656

10-24 UNC

9/32

.2812

“L”

.2900

“L”

.2900

19/64

.2969

10-32 UNF

9/32

.2812

“L”

.2900

“L”

.2900

19/64

.2969

1/4-20 UNC

3/8

.3750

3/8

.3750

“W”

.3860

25/64

.3906

5/16-18 UNC

1/2

.5000

1/2

.5000

33/64

.5156

33/64

.5156

3/8-16 UNC

9/16

.5625

9/16

.5625

37/64

.5781

37/64

.5781

1/2-13 UNC

3/4

.7500

49/64

.7656

25/32

.7810

51/64

.7970

0,76 - 2,29 MAT. THICKNESS

2,31 - 3,15 MAT. THICKNESS

3,17 - 4,72 MAT. THICKNESS

4,72 - OVER MAT. THICKNESS

THREAD

SIZE

DRILL SIZE

DECIMAL

DRILL SIZE

DECIMAL

DRILL SIZE

DECIMAL

DRILL SIZE

DECIMAL

M3 x 0,5 ISO

4,75

.1875

4,90

.1935

4,90

.1935

4,97

.1960

M4 x 0,7 ISO

6,35

.2500

6,52

.2570

6,74

.2656

6,74

.2656

M5 x 0,8 ISO

7,14

.2812

7,36

.2900

7,36

.2900

7,54

.2969

M6 x 1,0 ISO

9,52

.3750

9,52

.3750

9,80

.3860

9,92

.3906

M8 x 1,25 ISO

12,70

.5000

12,70

.5000

13,09

.5156

13,09

.5156

M10 x 1,5 ISO

14,28

.5625

14,28

.5625

14,68

.5781

14,68

.5781

M12 x 1,75 ISO

19,05

.7500

19,44

.7656

19,83

.7810

20,24

.7970

FINISH:The standard specified finish for the A-T Series Insert is tin. Alteration to this finish will reduce performance.*THREAD CLASS:The A-T Series Insert’s internal threads

are manufactured oversized to compensate for resulting thread portion shrinkage during the installation swaging process. They are not gaugeable prior to or after

installation but will be compatible with Class 2A/3A or 6g screws after installation.

NOTE: Hole sizes: The application should be tested before hole size is specified.

MATERIAL TYPE

PART NUMBERING SYSTEM

IDENTIFICATION GROOVES

All materials for the A-T Series

when plated look similar. Radial

SAMPLE NUMBER: ATS5-610

grooves are machined into the

part for material identification.

( )

( )

( )

- ( )

AT

PRODUCT

THREAD

TYPE

MATERIAL

FINISH RoHS COMPLIANT

SERIES

CALL OUT

CALL

CALL

CALL

SPECIFICATION

TYPE

GRADE

OUT

OUT

OUT

Open End

S

2

Steel , Low Carbon

BLANK

CAD PLATE PER AMS-QQ-P-416, TY I CLASS 3

NONE

STEEL

502

Closed End

A

Aluminum 6061-T6

3R

PLAIN ZINC PER ASTM-B-633, FE/ZN .0003 (8µ)

1

STAINLESS

2

BRASS

B

Brass 360 or 464

5

DULL TIN PER MIL-T-10727 TY I .0003

Index

3

ALUMINUM

C

CRES 304

9T

TIN ZINC TRIVALENT PER ESP-P-008, .0003 (8µ)

23

a d v a n c e c o m p o n e n t s . c o m

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1