Samples Job Safety Analysis Page 10

ADVERTISEMENT

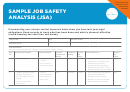

Appendix A illustrates a format that can be

This part of the analysis is usually prepared by

used as a worksheet for JSA.

watching the employee do the job. The

employee being observed should be experi-

Dividing a job into tasks requires a thor-

enced and capable of performing all parts of

ough knowledge of the job. If the tasks are

the job. The observation team may include

made too general, specific operations and

the immediate supervisor, a health and safety

related hazards may be missed. On the other

professional, and a member of the health and

hand, too many tasks may make the JSA

safety committee or the health and safety rep-

impractical. A rule of thumb is that most

resentative. Key points are less likely to be

jobs can be described in less than ten tasks.

missed in this way.

If more operational steps are required, it is

advisable to break the job into two seg-

ments, each with a separate JSA. As an

example, Table 1 presents the tasks involved

in changing a flat tire.

Table 1. An example of JSA applied to changing a flat tire.

JOB SAFETY ANALYSIS WORKSHEET

JOB: changing tire on a vehicle

Analysed by: John Supervisor and Tom Worker

Date: 29 May 2001

Reviewed by: Joe Expert

Date: 1 June 2001

Approved by: Co-Chairs Health and Safety Committee

Date: 5 June 2001

Sequence of Tasks

Potential Hazards

Preventive Measures

1. Park vehicle.

2. Get spare tire and tool kit.

3. Pry off hub cap.

4. Loosen lug bolts (nuts).

5. And so on ……..

4

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35 36

36 37

37 38

38 39

39 40

40 41

41 42

42