Ambs Imperial (U.s.) Bolts Torque Tightening Chart Page 2

ADVERTISEMENT

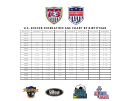

TIGHTENING TORQUES FOR METRIC BOLTS

80%

of yield strength (Sy)

MÉTRIQUE

Diameter (mm)

6

8

10

12

14

16

18

20

22

24

27

30

33

36

39

42

45

48

52

56

60

64

68

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

M33

M36

M39

M42

M45

M48

M52

M56

M60

M64

M68

1

1.25

1.5

1.75

2

2

2.5

2.5

2.5

3

3

3.5

3.5

4

4

4.5

4.5

5

5

5.5

5.5

6

6

PITCH (mm)

STRESS AREA (As) In mm²

20

37

58

84

115

157

192

245

303

353

459

561

694

817

976

1121

1306

1473

1758

2030

2362

2676

3055

TIGHTENING TORQUE in Lbs·ft

Multiply by 1.356 to obtain N*m

MATERIAL

LUBR.

µ

Sy (MPa)

NL

3

8

16

29

46

71

98

139

189

240

351

476

648

833

1078

1333

1665

2003

2589

3220

4014

4851

5884

CLASS 4.6

240

0.20

L

3

6

12

21

34

53

74

104

142

180

263

357

486

625

808

1000

1248

1502

1942

2415

3010

3638

4413

240

0.15

S

NL

9

22

44

76

122

189

262

370

504

639

937

1270

1729

2221

2874

3556

4439

5341

6904

8586

10704

12935

15691

CLASS 8.8

640

0.20

T

L

7

17

33

57

92

142

196

277

378

479

703

953

1296

1665

2156

2667

3329

4005

5178

6439

8028

9701

11769

640

0.15

A

NL

3

7

14

25

40

62

86

121

165

210

307

417

567

729

943

1167

1456

1752

2265

2817

3512

4244

5149

STAINLESS

210

0.20

N

L

2

5

11

19

30

47

64

91

124

157

231

313

425

546

707

875

1092

1314

1699

2113

2634

3183

3862

Class 50

210

0.15

D

NL

6

16

31

54

86

133

184

260

N/A, See note 1

STAINLESS

450

0.20

A

NL

N/A, See note 1

197

250

366

496

675

867

1123

1389

1734

2086

2697

3354

4181

5053

6129

Class 70

250

0.20

R

L

5

12

23

40

64

100

138

195

N/A, See note 1

450

0.15

D

L

N/A, See note 1

148

187

274

372

506

651

842

1042

1300

1565

2023

2515

3136

3789

4597

250

0.15

NL

9

21

41

72

114

177

245

347

473

599

878

1191

1621

2082

2694

3333

4161

5007

6472

8049

10035

12126

14711

STAINLESS

600

0.20

P

L

6

16

31

54

86

133

184

260

354

449

659

893

1215

1561

2021

2500

3121

3755

4854

6037

7526

9095

11033

Class 80

600

0.15

I

NL

4

9

17

30

48

74

102

144

197

250

366

496

675

867

1123

1389

1734

2086

2697

3354

4181

5053

6129

ASTM A36

250

0.20

T

L

3

6

13

22

36

55

77

108

148

187

274

372

506

651

842

1042

1300

1565

2023

2515

3136

3789

4597

250

0.15

C

NL

4

11

21

37

59

92

127

179

244

309

454

615

837

1076

1392

1722

2150

2587

3344

4159

5185

6265

7600

AISI 1045

310

0.20

H

L

3

8

16

28

44

69

95

134

183

232

340

461

628

807

1044

1292

1612

1940

2508

3119

3888

4699

5700

310

0.15

NL

6

15

29

50

80

124

172

243

331

419

615

834

1134

1457

1886

2333

2913

3505

4531

5635

7024

8488

10297

AISI 4140

420

0.20

L

4

11

22

38

60

93

129

182

248

314

461

625

851

1093

1415

1750

2185

2629

3398

4226

5268

6366

7723

420

0.15

NL

13

32

64

112

179

278

384

543

740

938

1376

1866

2539

3262

4221

5222

6519

7844

10140

12611

15721

18998

23047

CLASS 10.9

940

0.20

L

10

24

48

84

134

209

288

407

555

704

1032

1399

1904

2446

3166

3917

4889

5883

7605

9458

11791

14249

17285

940

0.15

NL

16

38

75

131

210

325

450

636

866

1098

1610

2183

2971

3817

4940

6111

7629

9179

11866

14757

18397

22232

26970

CLASS 12.9

1100

0.20

L

12

29

56

98

157

244

337

477

650

824

1208

1637

2228

2863

3705

4583

5722

6884

8899

11068

13798

16674

20227

1100

0.15

0.75

1

1

1.25

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

2

4

4

4

PITCH (mm)

STRESS AREA (As) In mm²

22

39

64

92

125

167

216

272

333

401

514

642

784

940

1110

1294

1493

1810

2010

2301

2485

2851

3242

TIGHTENING TORQUE in Lbs·ft

Multiply by 1.356 to obtain N*m

MATERIAL

LUBR.

µ

Sy (MPa)

NL

4

9

18

31

49

76

110

154

208

273

393

546

733

958

1226

1539

1902

2460

2961

3649

4223

5167

6244

CLASS 4.6

240

0.20

L

3

7

14

23

37

57

83

115

156

204

295

409

550

719

920

1155

1427

1845

2221

2737

3167

3876

4683

240

0.15

NL

10

24

49

83

132

202

294

410

553

727

1049

1455

1954

2555

3269

4105

5073

6560

7895

9731

11260

13780

16650

CLASS 8.8

640

0.20

L

7

18

37

63

99

152

220

308

415

545

787

1091

1465

1917

2452

3079

3804

4920

5921

7298

8445

10335

12487

640

0.15

F

NL

3

8

16

27

43

66

96

135

182

238

344

477

641

838

1073

1347

1664

2153

2591

3193

3695

4521

5463

STAINLESS

210

0.20

I

L

2

6

12

21

32

50

72

101

136

179

258

358

481

629

805

1010

1248

1614

1943

2395

2771

3391

4097

Class 50

210

0.15

N

NL

7

17

34

59

93

142

207

288

N/A, See note 1

STAINLESS

450

0.20

E

NL

N/A, See note 1

216

284

410

568

763

998

1277

1604

1981

2563

3084

3801

4398

5383

6504

Class 70

250

0.20

L

5

12

26

44

69

107

155

216

N/A, See note 1

450

0.15

P

L

N/A, See note 1

162

213

307

426

572

749

958

1203

1486

1922

2313

2851

3299

4037

4878

250

0.15

I

NL

9

22

46

78

123

189

276

384

519

681

983

1364

1832

2396

3065

3849

4756

6150

7402

9123

10556

12919

15609

STAINLESS

600

0.20

T

L

7

17

34

59

93

142

207

288

389

511

738

1023

1374

1797

2299

2886

3567

4613

5551

6842

7917

9689

11707

Class 80

600

0.15

C

NL

4

9

19

33

51

79

115

160

216

284

410

568

763

998

1277

1604

1981

2563

3084

3801

4398

5383

6504

ASTM A36

250

0.20

H

L

3

7

14

24

39

59

86

120

162

213

307

426

572

749

958

1203

1486

1922

2313

2851

3299

4037

4878

250

0.15

NL

5

11

24

40

64

98

142

199

268

352

508

705

946

1238

1584

1988

2457

3178

3824

4713

5454

6675

8065

AISI 1045

310

0.20

L

4

9

18

30

48

73

107

149

201

264

381

529

710

928

1188

1491

1843

2383

2868

3535

4091

5006

6049

310

0.15

NL

7

16

32

55

86

133

193

269

363

477

688

955

1282

1677

2146

2694

3329

4305

5181

6386

7389

9043

10926

AISI 4140

420

0.20

L

5

12

24

41

65

99

145

202

272

358

516

716

962

1258

1609

2021

2497

3229

3886

4789

5542

6782

8195

420

0.15

NL

15

35

72

123

193

297

432

602

813

1067

1541

2137

2870

3753

4802

6030

7450

9635

11596

14292

16538

20239

24454

CLASS 10.9

940

0.20

L

11

26

54

92

145

223

324

452

610

800

1156

1603

2152

2815

3601

4522

5588

7226

8697

10719

12404

15179

18341

940

0.15

NL

17

41

84

143

226

347

505

705

951

1249

1803

2501

3358

4392

5619

7056

8718

11275

13570

16725

19353

23684

28617

CLASS 12.9

1100

0.20

L

13

31

63

108

170

261

379

529

713

937

1352

1875

2519

3294

4214

5292

6539

8456

10178

12544

14515

17763

21462

1100

0.15

Lubrication: NL = Non-lubricated

L = Lubricated or New

As = 0.7854 * Pi * (D - (0.9382 * Pitch))^2

D = bolt diameter, in in.

F = % * Sy * As (% = % of yield strength, generally 80%)

C = F*µ*D = % * Sy * As * µ * D/1000

Sy = yield strength, in MPa

Note 1 : Stainless, class 70, Sy=250 MPa when D > 22mm

As = stress area of bolt, in mm²

P = Pitch in mm

F = tensile force, in N

C = TIGHTENING TORQUE IN N*m

µ = friction coefficient

C:\Documents and Settings\Alain\Mes documents\Couple de serrage.xls, 03.05.23 by A.S.

Notice: ABMS verify the accuracy of information we put on our website; however, errors may occur and the end user assumes all risk and liability from the use of this information.

ABMS Consultants inc., Consultant en ingénierie mécanique.

39, de la Baie, Granby, QC, J2G 8C8

Tél. (450) 378-6963, Téléc. (450) 378-9421, Courriel : alain.scuvee@abms.ca, Internet :

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1 2

2