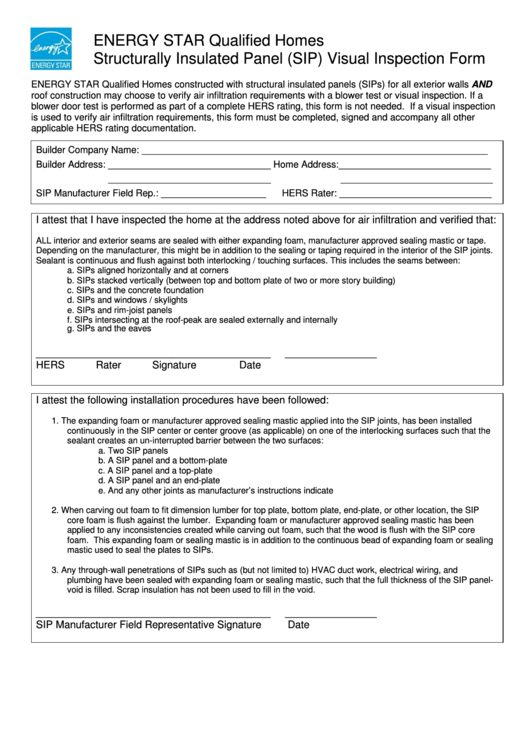

Energy Star Qualified Homes Structurally Insulated Panel (Sip) Visual Inspection Form

ADVERTISEMENT

ENERGY STAR Qualified Homes

Structurally Insulated Panel (SIP) Visual Inspection Form

ENERGY STAR Qualified Homes constructed with structural insulated panels (SIPs) for all exterior walls AND

roof construction may choose to verify air infiltration requirements with a blower test or visual inspection. If a

blower door test is performed as part of a complete HERS rating, this form is not needed. If a visual inspection

is used to verify air infiltration requirements, this form must be completed, signed and accompany all other

applicable HERS rating documentation.

Builder Company Name: __________________________________________________________________

Builder Address: _______________________________ Home Address:_____________________________

_______________________________

_____________________________

SIP Manufacturer Field Rep.: ____________________

HERS Rater: _____________________________

I attest that I have inspected the home at the address noted above for air infiltration and verified that:

ALL interior and exterior seams are sealed with either expanding foam, manufacturer approved sealing mastic or tape.

Depending on the manufacturer, this might be in addition to the sealing or taping required in the interior of the SIP joints.

Sealant is continuous and flush against both interlocking / touching surfaces. This includes the seams between:

a. SIPs aligned horizontally and at corners

b. SIPs stacked vertically (between top and bottom plate of two or more story building)

c. SIPs and the concrete foundation

d. SIPs and windows / skylights

e. SIPs and rim-joist panels

f.

SIPs intersecting at the roof-peak are sealed externally and internally

g. SIPs and the eaves

_________________________________________

________________

HERS Rater Signature

Date

I attest the following installation procedures have been followed:

1. The expanding foam or manufacturer approved sealing mastic applied into the SIP joints, has been installed

continuously in the SIP center or center groove (as applicable) on one of the interlocking surfaces such that the

sealant creates an un-interrupted barrier between the two surfaces:

a. Two SIP panels

b. A SIP panel and a bottom-plate

c. A SIP panel and a top-plate

d. A SIP panel and an end-plate

e. And any other joints as manufacturer’s instructions indicate

2. When carving out foam to fit dimension lumber for top plate, bottom plate, end-plate, or other location, the SIP

core foam is flush against the lumber. Expanding foam or manufacturer approved sealing mastic has been

applied to any inconsistencies created while carving out foam, such that the wood is flush with the SIP core

foam. This expanding foam or sealing mastic is in addition to the continuous bead of expanding foam or sealing

mastic used to seal the plates to SIPs.

3. Any through-wall penetrations of SIPs such as (but not limited to) HVAC duct work, electrical wiring, and

plumbing have been sealed with expanding foam or sealing mastic, such that the full thickness of the SIP panel-

void is filled. Scrap insulation has not been used to fill in the void.

_________________________________________

________________

SIP Manufacturer Field Representative Signature

Date

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1