Backflow Prevention Assembly Test And Maintenance Report

ADVERTISEMENT

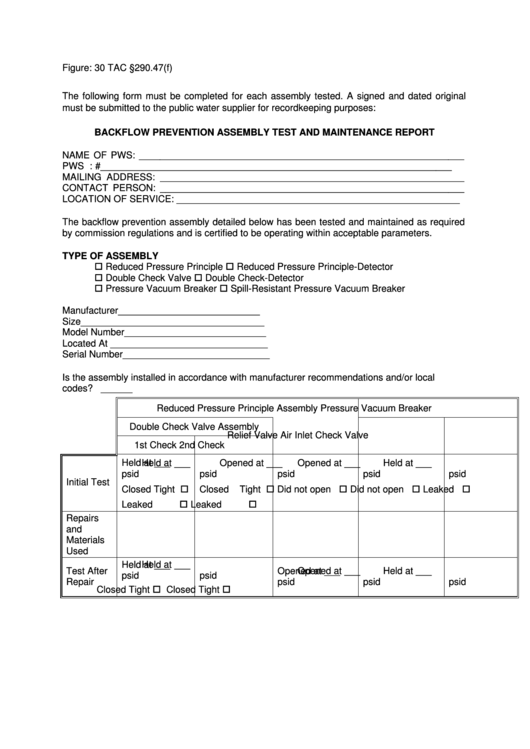

Figure: 30 TAC §290.47(f)

The following form must be completed for each assembly tested. A signed and dated original

must be submitted to the public water supplier for recordkeeping purposes:

BACKFLOW PREVENTION ASSEMBLY TEST AND MAINTENANCE REPORT

NAME OF PWS: ______________________________________________________________

PWS I.D.: #___________________________________________________________________

MAILING ADDRESS: __________________________________________________________

CONTACT PERSON: __________________________________________________________

LOCATION OF SERVICE: ______________________________________________________

The backflow prevention assembly detailed below has been tested and maintained as required

by commission regulations and is certified to be operating within acceptable parameters.

TYPE OF ASSEMBLY

Reduced Pressure Principle

Reduced Pressure Principle-Detector

Double Check Valve

Double Check-Detector

Pressure Vacuum Breaker

Spill-Resistant Pressure Vacuum Breaker

Manufacturer___________________________

Size___________________________________

Model Number___________________________

Located At ______________________________

Serial Number____________________________

Is the assembly installed in accordance with manufacturer recommendations and/or local

codes? ______

Reduced Pressure Principle Assembly

Pressure Vacuum Breaker

Double Check Valve Assembly

Relief Valve

Air Inlet

Check Valve

1st Check

2nd Check

Held at ___

Held at ___

Opened at ___

Opened at ___

Held at ___

psid

psid

psid

psid

psid

Initial Test

Closed Tight

Closed Tight

Did not open

Did not open

Leaked

Leaked

Leaked

Repairs

and

Materials

Used

Held at ___

Held at ___

Test After

Opened at ___

Opened at ___

Held at ___

psid

psid

Repair

psid

psid

psid

Closed Tight

Closed Tight

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2