Backflow Prevention Assembly Test Data And Maintenance Report Form

ADVERTISEMENT

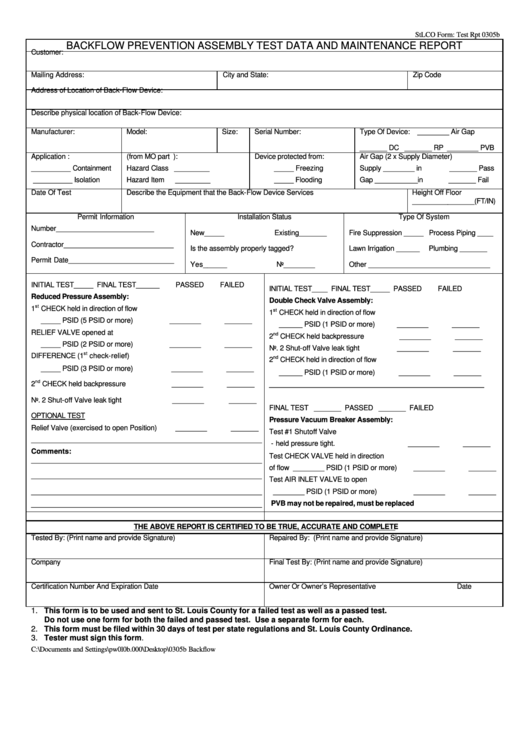

StLCO Form: Test Rpt 0305b

BACKFLOW PREVENTION ASSEMBLY TEST DATA AND MAINTENANCE REPORT

Customer:

Mailing Address:

City and State:

Zip Code

Address of Location of Back-Flow Device:

Describe physical location of Back-Flow Device:

Manufacturer:

Model:

Size:

Serial Number:

Type Of Device: ________ Air Gap

_______ DC _______ RP ________ PVB

Application :

(from MO part 10.CSR 11.010):

Device protected from:

Air Gap (2 x Supply Diameter)

__________ Containment

Hazard Class _________

_____ Freezing

Supply ________ in

_______ Pass

__________ Isolation

Hazard Item

_________

_____ Flooding

Gap ___________in

_______ Fail

Date Of Test

Describe the Equipment that the Back-Flow Device Services

Height Off Floor

________________(FT/IN)

Permit Information

Installation Status

Type Of System

Number_________________________

New_____

Existing_______

Fire Suppression _____ Process Piping ____

Contractor____________________________

Is the assembly properly tagged?

Lawn Irrigation ______

Plumbing _______

Permit Date___________________________

Yes______

No________

Other _______________________________

INITIAL TEST_____ FINAL TEST______

PASSED

FAILED

INITIAL TEST____ FINAL TEST_____ PASSED

FAILED

Reduced Pressure Assembly:

Double Check Valve Assembly:

st

1

CHECK held in direction of flow

st

1

CHECK held in direction of flow

_____ PSID (5 PSID or more)

________

_______

______ PSID (1 PSID or more)

________

_______

RELIEF VALVE opened at

nd

2

CHECK held backpressure

________

_______

_____ PSID (2 PSID or more)

________

_______

No. 2 Shut-off Valve leak tight

________

_______

st

DIFFERENCE (1

check-relief)

nd

2

CHECK held in direction of flow

_____ PSID (3 PSID or more)

________

_______

______ PSID (1 PSID or more)

________

_______

nd

2

CHECK held backpressure

________

_______

_______________________________________________________

No. 2 Shut-off Valve leak tight

________

_______

FINAL TEST _______ PASSED _______ FAILED

OPTIONAL TEST

Pressure Vacuum Breaker Assembly:

Relief Valve (exercised to open Position)

________

_______

Test #1 Shutoff Valve

___________________________________________________________

- held pressure tight.

________

_______

Comments:

Test CHECK VALVE held in direction

___________________________________________________________

of flow ________ PSID (1 PSID or more)

________

_______

___________________________________________________________

Test AIR INLET VALVE to open

___________________________________________________________

________ PSID (1 PSID or more)

________

_______

PVB may not be repaired, must be replaced

___________________________________________________________

THE ABOVE REPORT IS CERTIFIED TO BE TRUE, ACCURATE AND COMPLETE

Tested By: (Print name and provide Signature)

Repaired By: (Print name and provide Signature)

Company

Final Test By: (Print name and provide Signature)

Certification Number And Expiration Date

Owner Or Owner’s Representative

Date

1. This form is to be used and sent to St. Louis County for a failed test as well as a passed test.

Do not use one form for both the failed and passed test. Use a separate form for each.

2. This form must be filed within 30 days of test per state regulations and St. Louis County Ordinance.

3. Tester must sign this form.

C:\Documents and Settings\pw0l0b.000\Desktop\0305b Backflow Form.doc

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1