Microflex Glove Size Chart

ADVERTISEMENT

The Microflex® Difference in Glove Sizing

“It fits like a glove…” How many times have we heard this phrase? The fit and feel of our gloves

are vitally important to Microflex and our customers. Our on-site Laboratory monitors various

glove dimensions including weight, length, palm width, cuff thickness, palm thickness and

fingertip thickness, to ensure our gloves meet expectations in these areas. The most important

dimensions in terms of fit, feel and sizing for the glove industry are length, palm width and

thickness. These characteristics when examined comprehensively give us the best picture of the

true size of a glove.

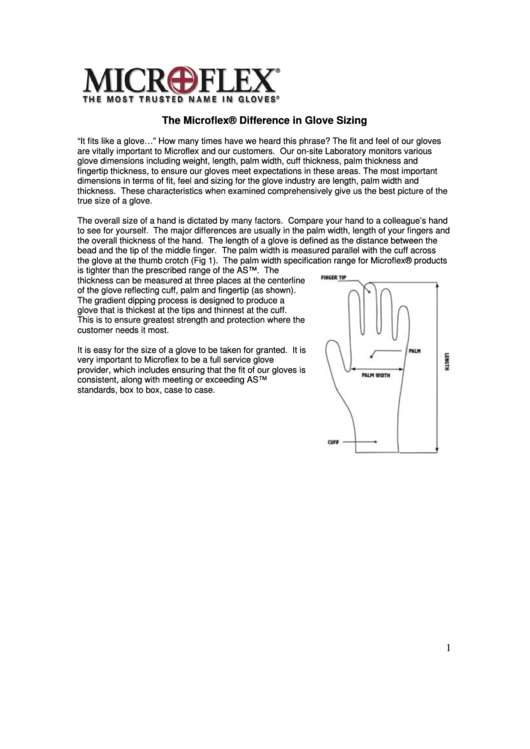

The overall size of a hand is dictated by many factors. Compare your hand to a colleague’s hand

to see for yourself. The major differences are usually in the palm width, length of your fingers and

the overall thickness of the hand. The length of a glove is defined as the distance between the

bead and the tip of the middle finger. The palm width is measured parallel with the cuff across

the glove at the thumb crotch (Fig 1). The palm width specification range for Microflex® products

is tighter than the prescribed range of the ASTM. The

thickness can be measured at three places at the centerline

of the glove reflecting cuff, palm and fingertip (as shown).

The gradient dipping process is designed to produce a

glove that is thickest at the tips and thinnest at the cuff.

This is to ensure greatest strength and protection where the

customer needs it most.

It is easy for the size of a glove to be taken for granted. It is

very important to Microflex to be a full service glove

provider, which includes ensuring that the fit of our gloves is

consistent, along with meeting or exceeding ASTM

standards, box to box, case to case.

1

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1 2

2