Operation And Maintenance Plan Template Page 6

ADVERTISEMENT

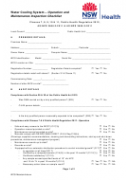

Frequency

(where

Maintenance Plan Checklist

applicable)

Gutters and associated piping are inspected for sound

connections and joints

Gutters are observed for leaks during rain events

Flush valves are maintained clear of debris

Trash and foreign material removed to prevent inadvertent

disposal in or clogging of liquid waste system

Corral feed aprons (where cows stand when eating) are flushed

to manure storage

Corral feed aprons scraped to manure storage

Corral feed apron runoff collected and transferred to liquid

storage system

Corrals sloped to drain directly into flush lane

Corrals sloped to drain to collection point & water pumped to

flush lane- automatic pump system

Corrals sloped to drain to collection point & water pumped to

flush lane- manual pump system

Exercise pens and open corrals are cleaned prior to the wet

season

Holes in corrals that may cause ponding are filled

Corrals are observed for ponding after rainfall

Corrals are managed in the rainy season to prevent ponding.

Corral manure mounds built and compacted prior to the rainy

season

Wet weather manure accumulation in corrals is checked to

determine the need for manure removal or corral grading

Unless diverted, rain run-on to housing and corrals is collected

and conveyed to the liquid manure storage system

Corrals scraped/harrowed weather permitting

Corral solid manure removed spring and fall

Corral solid manure removed prior to wet weather.

Manure removed from fence lines when corrals are cleaned

Rain runoff and surface drainage is diverted away from manured

areas

Rain runoff and surface drainage are collected and conveyed to

liquid storage system.

Diversion piping used to divert storm water run-off checked

before and during rain season to ensure freedom from blockage

5 of 9

Version 3-4-08, page

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10