Standard Form 368 Instructions - Search Results Product Quality Deficiency Report

ADVERTISEMENT

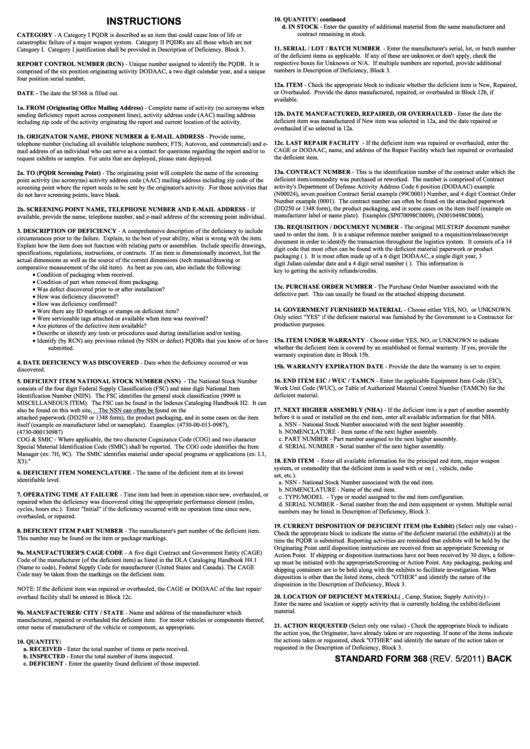

INSTRUCTIONS

10. QUANTITY: continued

d. IN STOCK - Enter the quantity of additional material from the same manufacturer and

contract remaining in stock.

CATEGORY - A Category I PQDR is described as an item that could cause loss of life or

catastrophic failure of a major weapon system. Category II PQDRs are all those which are not

11. SERIAL / LOT / BATCH NUMBER - Enter the manufacturer's serial, lot, or batch number

Category I. Category I justification shall be provided in Description of Deficiency, Block 3.

of the deficient items as applicable. If any of these are unknown or don't apply, check the

respective boxes for Unknown or N/A. If multiple numbers are reported, provide additional

REPORT CONTROL NUMBER (RCN) - Unique number assigned to identify the PQDR. It is

numbers in Description of Deficiency, Block 3.

comprised of the six position originating activity DODAAC, a two digit calendar year, and a unique

four position serial number, e.g. M12000-10-0001.

12a. ITEM - Check the appropriate block to indicate whether the deficient item is New, Repaired,

or Overhauled. Provide the dates manufactured, repaired, or overhauled in Block 12b, if

DATE - The date the SF368 is filled out.

available.

1a. FROM (Originating Office Mailing Address) - Complete name of activity (no acronyms when

12b. DATE MANUFACTURED, REPAIRED, OR OVERHAULED - Enter the date the

sending deficiency report across component lines), activity address code (AAC) mailing address

deficient item was manufactured if New item was selected in 12a, and the date repaired or

including zip code of the activity originating the report and current location of the activity.

overhauled if so selected in 12a.

1b. ORIGINATOR NAME, PHONE NUMBER & E-MAIL ADDRESS - Provide name,

12c. LAST REPAIR FACILITY - If the deficient item was repaired or overhauled, enter the

telephone number (including all available telephone numbers; FTS; Autovon, and commercial) and e-

CAGE or DODAAC, name, and address of the Repair Facility which last repaired or overhauled

mail address of an individual who can serve as a contact for questions regarding the report and/or to

the deficient item.

request exhibits or samples. For units that are deployed, please state deployed.

13a. CONTRACT NUMBER - This is the identification number of the contract under which the

2a. TO (PQDR Screening Point) - The originating point will complete the name of the screening

deficient item/commodity was purchased or reworked. The number is comprised of Contract

point activity (no acronyms) activity address code (AAC) mailing address including zip code of the

activity's Department of Defense Activity Address Code 6 position (DODAAC) example

screening point where the report needs to be sent by the originator's activity. For those activities that

(N00024), seven position Contract Serial example (99C0001) Number, and 4 digit Contract Order

do not have screening points, leave blank.

Number example (0001). The contract number can often be found on the attached paperwork

(DD250 or 1348 form), the product packaging, and in some cases on the item itself (example on

2b. SCREENING POINT NAME, TELEPHONE NUMBER AND E-MAIL ADDRESS - If

manufacturer label or name plate). Examples (SP070098C0009), (N0010498C0008).

available, provide the name, telephone number, and e-mail address of the screening point individual.

13b. REQUISITION / DOCUMENT NUMBER - The original MILSTRIP document number

3. DESCRIPTION OF DEFICIENCY - A comprehensive description of the deficiency to include

used to order the item. It is a unique reference number assigned to a requisition/release/receipt

circumstances prior to the failure. Explain, to the best of your ability, what is wrong with the item.

document in order to identify the transaction throughout the logistics system. It consists of a 14

Explain how the item does not function with relating parts or assemblies. Include specific drawings,

digit code that most often can be found with the deficient material paperwork or product

specifications, regulations, instructions, or contracts. If an item is dimensionally incorrect, list the

packaging (e.g. 1348 form). It is most often made up of a 6 digit DODAAC, a single digit year, 3

actual dimensions as well as the source of the correct dimensions (tech manual/drawing or

digit Julian calendar date and a 4 digit serial number (e.g. N4511202334567). This information is

comparative measurement of the old item). As best as you can, also include the following:

key to getting the activity refunds/credits.

• Condition of packaging when received.

• Condition of part when removed from packaging.

13c. PURCHASE ORDER NUMBER - The Purchase Order Number associated with the

• Was defect discovered prior to or after installation?

defective part. This can usually be found on the attached shipping document.

• How was deficiency discovered?

• How was deficiency confirmed?

• Were there any ID markings or stamps on deficient item?

14. GOVERNMENT FURNISHED MATERIAL - Choose either YES, NO, or UNKNOWN.

• Were serviceable tags attached or available when item was received?

Only select “YES” if the deficient material was furnished by the Government to a Contractor for

• Are pictures of the defective item available?

production purposes.

• Describe or identify any tests or procedures used during installation and/or testing.

• Identify (by RCN) any previous related (by NSN or defect) PQDRs that you know of or have

15a. ITEM UNDER WARRANTY - Choose either YES, NO, or UNKNOWN to indicate

whether the deficient item is covered by an established or formal warranty. If yes, provide the

submitted.

warranty expiration date in Block 15b.

4. DATE DEFICIENCY WAS DISCOVERED - Date when the deficiency occurred or was

15b. WARRANTY EXPIRATION DATE - Provide the date the warranty is set to expire.

discovered.

16. END ITEM EIC / WUC / TAMCN - Enter the applicable Equipment Item Code (EIC),

5. DEFICIENT ITEM NATIONAL STOCK NUMBER (NSN) - The National Stock Number

Work Unit Code (WUC), or Table of Authorized Material Control Number (TAMCN) for the

consists of the four digit Federal Supply Classification (FSC) and nine digit National Item

deficient material.

Identification Number (NIIN). The FSC identifies the general stock classification (9999 is

MISCELLANEOUS ITEM). The FSC can be found in the Indexes Cataloging Handbook H2. It can

17. NEXT HIGHER ASSEMBLY (NHA) - If the deficient item is a part of another assembly

also be found on this web site, The NSN can often be found on the

before it is used or installed on the end item, enter all available information for that NHA.

attached paperwork (DD250 or 1348 form), the product packaging, and in some cases on the item

a. NSN - National Stock Number associated with the next higher assembly.

itself (example on manufacturer label or nameplate). Examples: (4730-00-013-0987),

b. NOMENCLATURE - Item name of the next higher assembly.

(4730-000130987)

c. PART NUMBER - Part number assigned to the next higher assembly.

COG & SMIC - Where applicable, the two character Cognizance Code (COG) and two character

d. SERIAL NUMBER - Serial number of the next higher assembly.

Special Material Identification Code (SMIC) shall be reported. The COG code identifies the Item

Manager (ex: 7H, 9C). The SMIC identifies material under special programs or applications (ex: L1,

18. END ITEM - Enter all available information for the principal end item, major weapon

X3)."

system, or commodity that the deficient item is used with or on (i.e. weapon system, vehicle, radio

6. DEFICIENT ITEM NOMENCLATURE - The name of the deficient item at its lowest

set, etc.).

identifiable level.

a. NSN - National Stock Number associated with the end item.

b. NOMENCLATURE - Name of the end item.

7. OPERATING TIME AT FAILURE - Time item had been in operation since new, overhauled, or

c. TYPE/MODEL - Type or model assigned to the end item configuration.

repaired when the deficiency was discovered citing the appropriate performance element (miles,

d. SERIAL NUMBER - Serial number from the end item equipment or system. Multiple serial

cycles, hours etc.). Enter "Initial” if the deficiency occurred with no operation time since new,

numbers may be listed in Description of Deficiency, Block 3.

overhauled, or repaired.

19. CURRENT DISPOSITION OF DEFICIENT ITEM (the Exhibit) (Select only one value) -

8. DEFICIENT ITEM PART NUMBER - The manufacturer's part number of the deficient item.

Check the appropriate block to indicate the status of the deficient material (the exhibit(s)) at the

This number may be found on the item or package markings.

time the PQDR is submitted. Reporting activities are reminded that exhibits will be held by the

Originating Point until disposition instructions are received from an appropriate Screening or

9a. MANUFACTURER'S CAGE CODE - A five digit Contract and Government Entity (CAGE)

Action Point. If shipping or disposition instructions have not been received by 30 days, a follow-

Code of the manufacturer (of the deficient item) as listed in the DLA Cataloging Handbook H4.1

up must be initiated with the appropriate Screening or Action Point. Any packaging, packing and

(Name to code), Federal Supply Code for manufacturer (United States and Canada). The CAGE

shipping containers are to be held along with the exhibits to facilitate investigation. When

Code may be taken from the markings on the deficient item.

disposition is other than the listed items, check "OTHER" and identify the nature of the

disposition in the Description of Deficiency, Block 3.

NOTE: If the deficient item was repaired or overhauled, the CAGE or DODAAC of the last repair/

.

20. LOCATION OF DEFICIENT MATERIAL (e.g. Base, Camp, Station, Supply Activity) -

overhaul facility shall be entered in Block 12c

Enter the name and location or supply activity that is currently holding the exhibit/deficient

material.

9b. MANUFACTURER / CITY / STATE - Name and address of the manufacturer which

manufactured, repaired or overhauled the deficient item. For motor vehicles or components thereof,

21. ACTION REQUESTED (Select only one value) - Check the appropriate block to indicate

enter name of manufacturer of the vehicle or component, as appropriate.

the action you, the Originator, have already taken or are requesting. If none of the items indicate

the actions taken or requested, check "OTHER" and identify the nature of the action taken or

10. QUANTITY:

requested in the Description of Deficiency, Block 3.

a. RECEIVED - Enter the total number of items or parts received.

STANDARD FORM 368 (REV. 5/2011) BACK

b. INSPECTED - Enter the total number of items inspected.

c. DEFICIENT - Enter the quantity found deficient of those inspected.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Legal

1

1