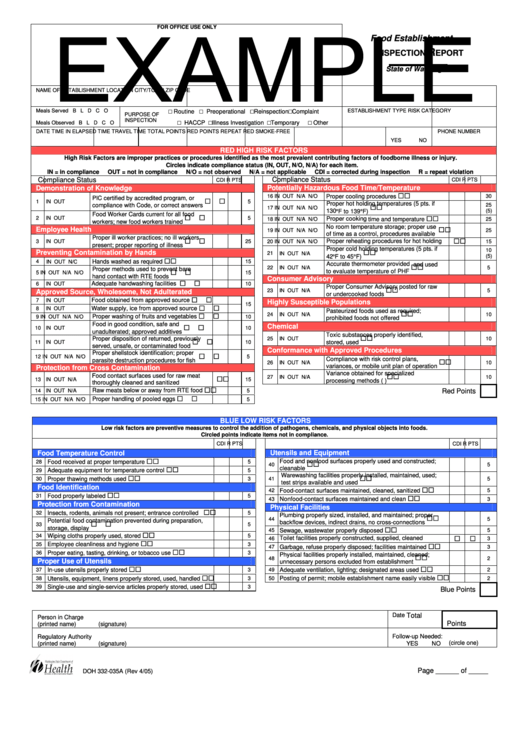

Food Establishment Inspection Report

ADVERTISEMENT

EXAMPLE

FOR OFFICE USE ONLY

F o o d E st ab li sh m en t

I

R

NSPECTION

EPORT

State of Washington

NAME OF ESTABLISHMENT

LOCATION

CITY/TOWN

ZIP CODE

Meals Served B L D C O

Routine

Preoperational

Reinspection

Complaint

ESTABLISHMENT TYPE

RISK CATEGORY

PURPOSE OF

INSPECTION

Meals Observed B L D C O

HACCP

Illness Investigation

Temporary

Other

DATE

TIME IN

ELAPSED TIME

TRAVEL TIME

TOTAL POINTS

RED POINTS

REPEAT RED

SMOKE-FREE

PHONE NUMBER

YES

NO

RED HIGH RISK FACTORS

High Risk Factors are improper practices or procedures identified as the most prevalent contributing factors of foodborne illness or injury.

Circles indicate compliance status (IN, OUT, N/O, N/A) for each item.

IN = in compliance

OUT = not in compliance

N/O = not observed

N/A = not applicable

CDI = corrected during inspection

R = repeat violation

Compliance Status

Compliance Status

CDI

R

PTS

CDI

R

PTS

Demonstration of Knowledge

Potentially Hazardous Food Time/Temperature

Proper cooling procedures

16

IN OUT N/A N/O

30

PIC certified by accredited program, or

1

IN OUT

5

Proper hot holding temperatures (5 pts. if

compliance with Code, or correct answers

25

17

IN OUT N/A N/O

130 °F to 139°F)

(5)

Food Worker Cards current for all food

2

IN OUT

5

Proper cooking time and temperature

18

IN OUT N/A N/O

25

workers; new food workers trained

No room temperature storage; proper use

Employee Health

19

IN OUT N/A N/O

25

of time as a control, procedures available

Proper ill worker practices; no ill workers

Proper reheating procedures for hot holding

3

IN OUT

25

20

IN OUT N/A N/O

15

present; proper reporting of illness

Proper cold holding temperatures (5 pts. if

10

Preventing Contamination by Hands

21

IN OUT N/A

42 °F to 45°F)

(5)

Hands washed as required

4

IN OUT N/O

15

Accurate thermometer provided and used

22

IN OUT N/A

5

Proper methods used to prevent bare

to evaluate temperature of PHF

5

IN OUT N/A N/O

15

hand contact with RTE foods

Consumer Advisory

Adequate handwashing facilities

6

IN OUT

10

Proper Consumer Advisory posted for raw

23

IN OUT N/A

5

Approved Source, Wholesome, Not Adulterated

or undercooked foods

Food obtained from approved source

7

IN OUT

Highly Susceptible Populations

15

Water supply, ice from approved source

8

IN OUT

Pasteurized foods used as required;

24

IN OUT N/A

10

Proper washing of fruits and vegetables

9

IN OUT N/A N/O

10

prohibited foods not offered

Food in good condition, safe and

Chemical

10 IN OUT

10

unadulterated; approved additives

Toxic substances properly identified,

Proper disposition of returned, previously

25

IN OUT

10

stored, used

11 IN OUT

10

served, unsafe, or contaminated food

Conformance with Approved Procedures

Proper shellstock identification; proper

12 IN OUT N/A N/O

5

Compliance with risk control plans,

parasite destruction procedures for fish

26

IN OUT N/A

10

variances, or mobile unit plan of operation

Protection from Cross Contamination

Variance obtained for specialized

Food contact surfaces used for raw meat

27

IN OUT N/A

10

13 IN OUT N/A

15

processing methods (e.g. ROP)

thoroughly cleaned and sanitized

Raw meats below or away from RTE food

Red Points

14 IN OUT N/A

5

Proper handling of pooled eggs

15 IN OUT N/A N/O

5

BLUE LOW RISK FACTORS

Low risk factors are preventive measures to control the addition of pathogens, chemicals, and physical objects into foods.

Circled points indicate items not in compliance.

CDI

R

PTS

CDI

R

PTS

Food Temperature Control

Utensils and Equipment

Food and nonfood surfaces properly used and constructed;

Food received at proper temperature

28

5

40

5

cleanable

Adequate equipment for temperature control

29

5

Warewashing facilities properly installed, maintained, used;

Proper thawing methods used

30

3

41

5

test strips available and used

Food Identification

Food-contact surfaces maintained, cleaned, sanitized

42

5

Food properly labeled

31

5

Nonfood-contact surfaces maintained and clean

43

3

Protection from Contamination

Physical Facilities

32

Insects, rodents, animals not present; entrance controlled

5

Plumbing properly sized, installed, and maintained; proper

44

5

Potential food contamination prevented during preparation,

backflow devices, indirect drains, no cross-connections

33

5

storage, display

Sewage, wastewater properly disposed

45

5

Wiping cloths properly used, stored

34

5

Toilet facilities properly constructed, supplied, cleaned

46

3

Employee cleanliness and hygiene

35

3

Garbage, refuse properly disposed; facilities maintained

47

3

36

Proper eating, tasting, drinking, or tobacco use

3

Physical facilities properly installed, maintained, cleaned;

48

2

Proper Use of Utensils

unnecessary persons excluded from establishment

In-use utensils properly stored

Adequate ventilation, lighting; designated areas used

37

3

49

2

Utensils, equipment, linens properly stored, used, handled

Posting of permit; mobile establishment name easily visible

38

3

50

2

Single-use and single-service articles properly stored, used

39

3

Blue Points

Date

Total

Person in Charge

Points

(printed name)

(signature)

Regulatory Authority

Follow-up Needed:

(printed name)

(signature)

YES

NO

(circle one)

Page ______ of _____

DOH 332-035A (Rev 4/05)

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2