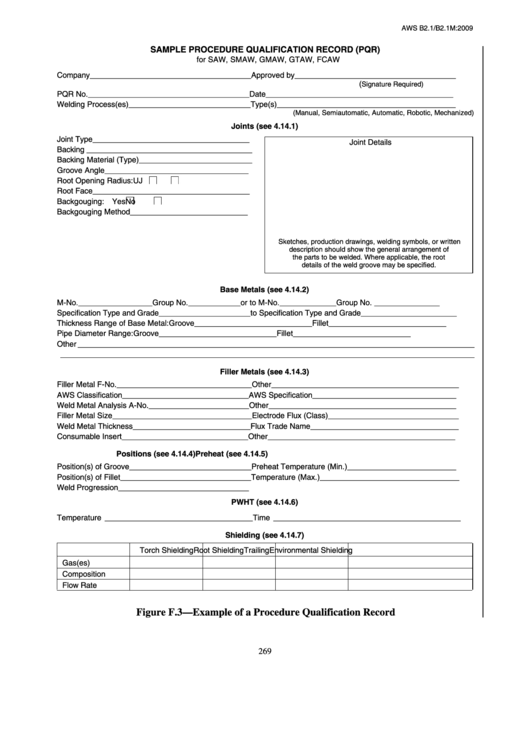

AWS B2.1/B2.1M:2009

SAMPLE PROCEDURE QUALIFICATION RECORD (PQR)

for SAW, SMAW, GMAW, GTAW, FCAW

Company_____________________________________

Approved by _____________________________________

Approved by

(

Signature Required)

PQR No. _____________________________________

Date ___________________________________________

Welding Process(es) ____________________________

Type(s) _________________________________________

(Manual, Semiautomatic, Automatic, Robotic, Mechanized)

Joints (see 4.14.1)

Joint Type ____________________________________

Joint Details

Backing ______________________________________

Backing Material (Type)__________________________

Groove Angle _________________________________

Root Opening Radius: U

J

Root Face ____________________________________

Backgouging: Yes

No

Backgouging Method ___________________________

Sketches, production drawings, welding symbols, or written

description should show the general arrangement of

the parts to be welded. Where applicable, the root

details of the weld groove may be specified.

Base Metals (see 4.14.2)

M-No. _________________ Group No. ____________

or to M-No. _____________ Group No. _______________

Specification Type and Grade _____________________

to Specification Type and Grade ______________________

Thickness Range of Base Metal:

Groove___________________________

Fillet___________________________

Pipe Diameter Range:

Groove___________________________

Fillet___________________________

Other ___________________________________________________________________________________________

_______________________________________________________________________________________________

Filler Metals (see 4.14.3)

Filler Metal F-No._______________________________

Other ___________________________________________

AWS Classification _____________________________

AWS Specification_________________________________

Weld Metal Analysis A-No. _______________________

Other ___________________________________________

Filler Metal Size________________________________

Electrode Flux (Class)______________________________

Weld Metal Thickness ___________________________

Flux Trade Name__________________________________

Consumable Insert _____________________________

Other ___________________________________________

Positions (see 4.14.4)

Preheat (see 4.14.5)

Position(s) of Groove____________________________

Preheat Temperature (Min.) _________________________

Position(s) of Fillet______________________________

Temperature (Max.)________________________________

Weld Progression ______________________________

PWHT (see 4.14.6)

Temperature __________________________________

Time ___________________________________________

Shielding (see 4.14.7)

Torch Shielding

Root Shielding

Trailing

Environmental Shielding

Gas(es)

Composition

Flow Rate

Figure F.3—Example of a Procedure Qualification Record

269

1

1 2

2