Quality Coordinator Job Description

ADVERTISEMENT

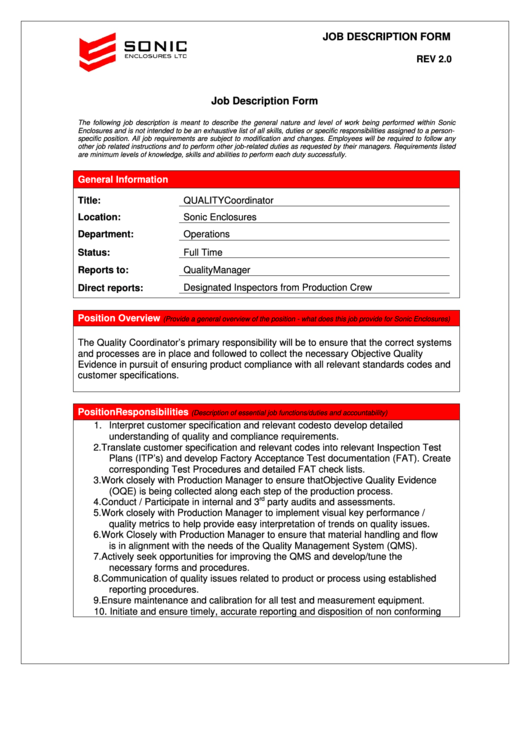

JOB DESCRIPTION FORM

REV 2.0

Job Description Form

The following job description is meant to describe the general nature and level of work being performed within Sonic

Enclosures and is not intended to be an exhaustive list of all skills, duties or specific responsibilities assigned to a person-

specific position. All job requirements are subject to modification and changes. Employees will be required to follow any

other job related instructions and to perform other job-related duties as requested by their managers. Requirements listed

are minimum levels of knowledge, skills and abilities to perform each duty successfully.

General Information

QUALITY Coordinator

Title:

Location:

Sonic Enclosures

Operations

Department:

Status:

Full Time

Reports to:

Quality Manager

Direct reports:

Designated Inspectors from Production Crew

Position Overview

(Provide a general overview of the position - what does this job provide for Sonic Enclosures)

The Quality Coordinator’s primary responsibility will be to ensure that the correct systems

and processes are in place and followed to collect the necessary Objective Quality

Evidence in pursuit of ensuring product compliance with all relevant standards codes and

customer specifications.

Position Responsibilities

(Description of essential job functions/duties and accountability)

1. Interpret customer specification and relevant codes to develop detailed

understanding of quality and compliance requirements.

2. Translate customer specification and relevant codes into relevant Inspection Test

Plans (ITP’s) and develop Factory Acceptance Test documentation (FAT). Create

corresponding Test Procedures and detailed FAT check lists.

3. Work closely with Production Manager to ensure that Objective Quality Evidence

(OQE) is being collected along each step of the production process.

rd

4. Conduct / Participate in internal and 3

party audits and assessments.

5. Work closely with Production Manager to implement visual key performance /

quality metrics to help provide easy interpretation of trends on quality issues.

6. Work Closely with Production Manager to ensure that material handling and flow

is in alignment with the needs of the Quality Management System (QMS).

7. Actively seek opportunities for improving the QMS and develop/tune the

necessary forms and procedures.

8. Communication of quality issues related to product or process using established

reporting procedures.

9. Ensure maintenance and calibration for all test and measurement equipment.

10. Initiate and ensure timely, accurate reporting and disposition of non conforming

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3