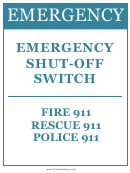

Appendix 1 Preventive Maintenance Checklist Emergency Standby Generators/switches/controls Page 2

ADVERTISEMENT

APPENDIX 1

PREVENTIVE MAINTENANCE CHECKLIST

EMERGENCY STANDBY GENERATORS/SWITCHES/CONTROLS

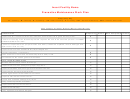

SECTION D – AIR INDUCTION & EXHAUST SYSTEM

SAT.

UNSAT.

(check one)

1. Air cleaner units/oil bath and dry type

2. Air induction piping and connections

3. Turbocharger/blower

4. Exhaust manifold/piping/connections

Note: Contractor is responsible for replacing air cleaners, all types.

SECTION E – POWER UNIT

SAT.

UNSAT.

(check one)

1. Generator structure

2. Clutch assembly (power take off)

3. Coupling(s)

SECTION F – LUBRICATION SYSTEM

SAT.

UNSAT.

(check one)

1. Engine oil level

2. Engine oil change

3. Engine oil filter change

4. Engine oil sample for analysis

5. Crankcase pressure

6. Crankcase breather

7. Oil leaks (hoses, connectors)

8. Engine governor oil level/linkage (UG8)

9. Fan drive bearings

10. Generator bearings

11. Engine starter oiler (air type only)

12. Gauges and safety mechanism

13. Accessory drives

Note: Contractor is responsible for replacing any and all engine oil, lubricant, filters and/or belts.

SECTION G – FUEL SYSTEM

SAT.

UNSAT.

(check one)

1. Fuel tank/day tank

2. Fuel filters-primary/secondary

3. Fuel system components/hoses/piping

4. Gauges and Safety mechanism

5. Condensation/water in fuel

Note: Contractor is responsible for replacing all fuel filters (primary and secondary)

REMARKS:

Technician: __________________________________________________

2

T1399 7/12/07

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Life

1

1 2

2