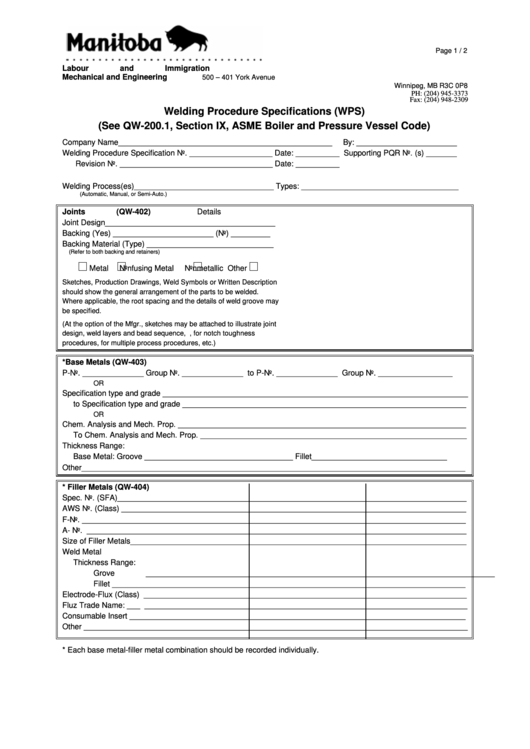

Welding Procedure Specifications (Wps) Form

ADVERTISEMENT

Page 1 / 2

Labour and Immigration

Mechanical and Engineering

500 – 401 York Avenue

Winnipeg, MB R3C 0P8

PH: (204) 945-3373

Fax: (204) 948-2309

Welding Procedure Specifications (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name_________________________________________________

By: _______________________

Welding Procedure Specification No. ___________________ Date: __________ Supporting PQR No. (s) _______

Revision No. ___________________________________ Date: __________

Welding Process(es)________________________________ Types: ____________________________________

(Automatic, Manual, or Semi-Auto.)

Joints (QW-402)

Details

Joint Design_______________________________________

Backing (Yes) _______________________ (No) _________

Backing Material (Type) _____________________________

(Refer to both backing and retainers)

Metal

Nonfusing Metal

Nonmetallic

Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded.

Where applicable, the root spacing and the details of weld groove may

be specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness

procedures, for multiple process procedures, etc.)

*Base Metals (QW-403)

P-No. ______________

Group No. ______________ to P-No. ______________ Group No. _________________

OR

Specification type and grade ______________________________________________________________________

to Specification type and grade _________________________________________________________________

OR

Chem. Analysis and Mech. Prop. __________________________________________________________________

To Chem. Analysis and Mech. Prop. _____________________________________________________________

Thickness Range:

Base Metal:

Groove __________________________________

Fillet_______________________________

Other________________________________________________________________________________________

* Filler Metals (QW-404)

Spec. No. (SFA)________________________________________________________________________________

AWS No. (Class) _______________________________________________________________________________

F-No. ________________________________________________________________________________________

A- No. _______________________________________________________________________________________

Size of Filler Metals_____________________________________________________________________________

Weld Metal

Thickness Range:

Grove ________________________________________________________________________________

Fillet _________________________________________________________________________________

Electrode-Flux (Class) __________________________________________________________________________

Fluz Trade Name: ___ __________________________________________________________________________

Consumable Insert _____________________________________________________________________________

Other ________________________________________________________________________________________

* Each base metal-filler metal combination should be recorded individually.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Legal

1

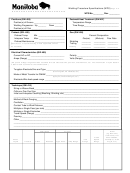

1 2

2