ANNEX N

AWS D1.1/D1.1M:2010

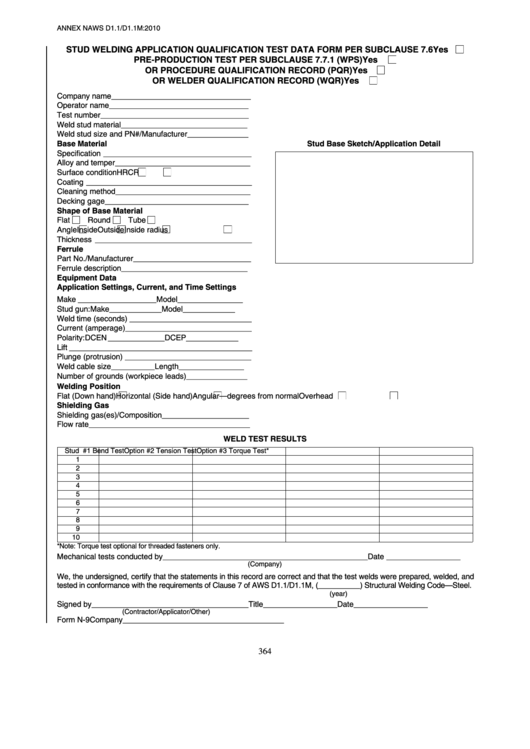

STUD WELDING APPLICATION QUALIFICATION TEST DATA FORM PER SUBCLAUSE 7.6 Yes

PRE-PRODUCTION TEST PER SUBCLAUSE 7.7.1 (WPS) Yes

OR PROCEDURE QUALIFICATION RECORD (PQR) Yes

OR WELDER QUALIFICATION RECORD (WQR) Yes

Company name________________________________

Operator name ________________________________

Test number __________________________________

Weld stud material _____________________________

Weld stud size and PN#/Manufacturer ______________

Base Material

Stud Base Sketch/Application Detail

Specification __________________________________

Alloy and temper _______________________________

Surface condition HR

CR

Coating ______________________________________

Cleaning method _______________________________

Decking gage _________________________________

Shape of Base Material

Flat

Round

Tube

Angle

Inside

Outside

Inside radius

Thickness ____________________________________

Ferrule

Part No./Manufacturer ___________________________

Ferrule description _____________________________

Equipment Data

Application Settings, Current, and Time Settings

Make __________________ Model _______________

Stud gun: Make ____________ Model ____________

Weld time (seconds) ____________________________

Current (amperage)_____________________________

Polarity: DCEN _____________ DCEP____________

Lift __________________________________________

Plunge (protrusion) _____________________________

Weld cable size __________ Length _______________

Number of grounds (workpiece leads) ______________

Welding Position

Flat (Down hand)

Horizontal (Side hand)

Angular—degrees from normal

Overhead

Shielding Gas

Shielding gas(es)/Composition ____________________

Flow rate _____________________________________

WELD TEST RESULTS

Stud No.

Visual Acceptance

Option #1 Bend Test

Option #2 Tension Test

Option #3 Torque Test*

1

2

3

4

5

6

7

8

9

100

*Note: Torque test optional for threaded fasteners only.

Mechanical tests conducted by _______________________________________________

Date _________________

(Company)

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in conformance with the requirements of Clause 7 of AWS D1.1/D1.1M, (__________ ) Structural Welding Code—Steel.

(year)

Signed by ____________________________________

Title _________________

Date _________________

(Contractor/Applicator/Other)

Form N-9

Company _____________________________________

364

1

1