Hazard Assessment Checklist

ADVERTISEMENT

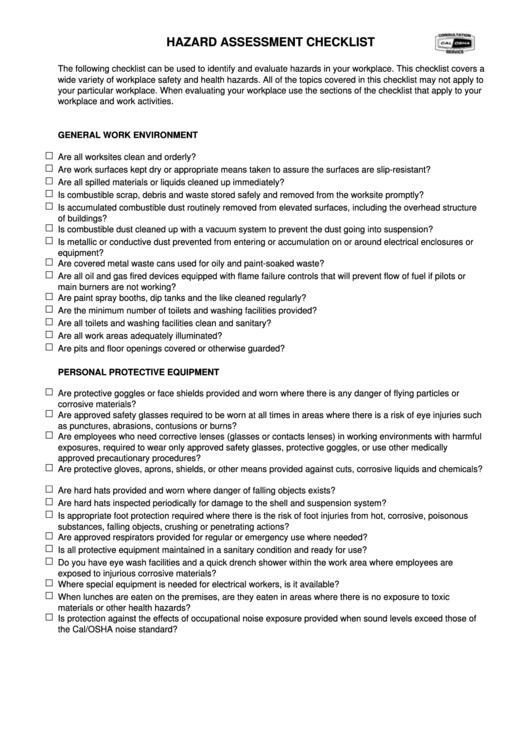

HAZARD ASSESSMENT CHECKLIST

The following checklist can be used to identify and evaluate hazards in your workplace. This checklist covers a

wide variety of workplace safety and health hazards. All of the topics covered in this checklist may not apply to

your particular workplace. When evaluating your workplace use the sections of the checklist that apply to your

workplace and work activities.

GENERAL WORK ENVIRONMENT

Are all worksites clean and orderly?

Are work surfaces kept dry or appropriate means taken to assure the surfaces are slip-resistant?

Are all spilled materials or liquids cleaned up immediately?

Is combustible scrap, debris and waste stored safely and removed from the worksite promptly?

Is accumulated combustible dust routinely removed from elevated surfaces, including the overhead structure

of buildings?

Is combustible dust cleaned up with a vacuum system to prevent the dust going into suspension?

Is metallic or conductive dust prevented from entering or accumulation on or around electrical enclosures or

equipment?

Are covered metal waste cans used for oily and paint-soaked waste?

Are all oil and gas fired devices equipped with flame failure controls that will prevent flow of fuel if pilots or

main burners are not working?

Are paint spray booths, dip tanks and the like cleaned regularly?

Are the minimum number of toilets and washing facilities provided?

Are all toilets and washing facilities clean and sanitary?

Are all work areas adequately illuminated?

Are pits and floor openings covered or otherwise guarded?

PERSONAL PROTECTIVE EQUIPMENT

Are protective goggles or face shields provided and worn where there is any danger of flying particles or

corrosive materials?

Are approved safety glasses required to be worn at all times in areas where there is a risk of eye injuries such

as punctures, abrasions, contusions or burns?

Are employees who need corrective lenses (glasses or contacts lenses) in working environments with harmful

exposures, required to wear only approved safety glasses, protective goggles, or use other medically

approved precautionary procedures?

Are protective gloves, aprons, shields, or other means provided against cuts, corrosive liquids and chemicals?

Are hard hats provided and worn where danger of falling objects exists?

Are hard hats inspected periodically for damage to the shell and suspension system?

Is appropriate foot protection required where there is the risk of foot injuries from hot, corrosive, poisonous

substances, falling objects, crushing or penetrating actions?

Are approved respirators provided for regular or emergency use where needed?

Is all protective equipment maintained in a sanitary condition and ready for use?

Do you have eye wash facilities and a quick drench shower within the work area where employees are

exposed to injurious corrosive materials?

Where special equipment is needed for electrical workers, is it available?

When lunches are eaten on the premises, are they eaten in areas where there is no exposure to toxic

materials or other health hazards?

Is protection against the effects of occupational noise exposure provided when sound levels exceed those of

the Cal/OSHA noise standard?

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19