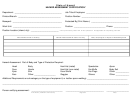

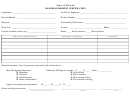

Hazard Assessment Checklist Page 16

ADVERTISEMENT

Is approved hearing protective equipment (noise attenuating devices) available to every employee working in

areas where continuous noise levels exceed 85 dBA?

If you use ear protectors, are employees properly fitted and instructed in their use and care?

Are employees exposed to continuous noise above 85 dBA given periodic audiometric testing to ensure that

you have an effective hearing protection system?

FUELING

Is it prohibited to fuel an internal combustion engine with a flammable liquid while the engine is running?

Are fueling operations done in such a manner that likelihood of spillage will be minimal?

When spillage occurs during fueling operations, is the spilled fuel cleaned up completely, evaporated, or other

measures taken to control vapors before restarting the engine?

Are fuel tank caps replaced and secured before starting the engine?

In fueling operations is there always metal contact between the container and fuel tank?

Are fueling hoses of a type designed to handle the specific type of fuel?

Is it prohibited to handle or transfer gasoline in open containers?

Are open lights, open flames, or sparking or arcing equipment prohibited near fueling or transfer of fuel

operations?

Is smoking prohibited in the vicinity of fueling operations?

Are fueling operations prohibited in building or other enclosed areas that are not specifically ventilated for this

purpose?

Where fueling or transfer of fuel is done through a gravity flow system, are the nozzles of the self-closing

type?

IDENTIFICATION OF PIPING SYSTEMS

When nonpotable water is piped through a facility, are outlets or taps posted to alert employees that it is

unsafe and not to be used for drinking, washing or other personal use?

When hazardous substances are transported through above ground piping, is each pipeline identified at points

where confusion could introduce hazards to employees?

When pipelines are identified by color painting, are all visible parts of the line so identified?

When pipelines are identified by color painted bands or tapes, are the bands or tapes located at reasonable

intervals and at each outlet, valve or connection?

When pipelines are identified by color, is the color code posted at all locations where confusion could

introduce hazards to employees?

When the contents of pipelines are identified by name or name abbreviation, is the information readily visible

on the pipe near each valve or outlet?

When pipelines carrying hazardous substances are identified by tags, are the tags constructed of durable

materials, the message carried clearly ad permanently distinguishable and are tags installed at each valve or

outlet?

When pipelines are heated by electricity, steam or other external source, are suitable warning signs or tags

placed at unions, valves, or other serviceable parts of the system?

MATERIAL HANDLING

Is there safe clearance for equipment through aisles and doorways?

Are aisleways designated, permanently marked, and kept clear to allow unhindered passage?

Are motorized vehicles and mechanized equipment inspected daily or prior to use?

Are vehicles shut off and brakes set prior to loading or unloading?

Are containers or combustibles or flammables, when stacked while being moved, always separated by

dunnage sufficient to provide stability?

Are dock boards (bridge plates) used when loading or unloading operations are taking place between vehicles

and docks?

Are trucks and trailers secured from movement during loading and unloading operations?

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19