Hazard Assessment Checklist Page 9

ADVERTISEMENT

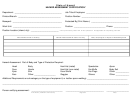

HOIST & AUXILIARY EQUIPMENT

Is each overhead electric hoist equipped with a limit device to stop the hook travel at its highest and lowest

point of safe travel?

Will each hoist automatically stop and hold any load up to 125 percent of its rated load, if its actuating force is

removed?

Is the rated load of each hoist legibly marked and visible to the operator?

Are stops provided at the safe limits of travel for trolley hoist?

Are the controls of hoists plainly marked to indicate the direction of travel or motion?

Is each cage-controlled hoist equipped with an effective warning device?

Are close-fitting guards or other suitable devices installed on hoist to assure hoist ropes will be maintained in

the sheave groves?

Are all hoist chains or ropes of sufficient length to handle the full range of movement for the application while

still maintaining two full wraps on the drum at all times?

Are nip points or contact points between hoist ropes and sheaves which are permanently located within 7 feet

of the floor, ground or working platform, guarded?

Is it prohibited to use chains or rope slings that are kinked or twisted?

Is it prohibited to use the hoist rope or chain wrapped around the load as a substitute, for a sling?

Is the operator instructed to avoid carrying loads over people?

Are only employees who have been trained in the proper use of hoists allowed to operate them?

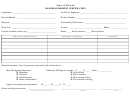

INDUSTRIAL TRUCKS - FORKLIFTS

Are only trained personnel allowed to operate industrial trucks?

Is substantial overhead protective equipment provided on high lift rider equipment?

Are the required lift truck operating rules posted and enforced?

Is directional lighting provided on each industrial truck that operates in an area with less than 2 foot candles

per square foot of general lighting?

Does each industrial truck have a warning horn, whistle, gong or other device which can be clearly heard

above the normal noise in the areas where operated?

Are the brakes on each industrial truck capable of bringing the vehicle to a complete and safe stop when fully

loaded?

Will the industrial truck's parking brake effectively prevent the vehicle from moving when unattended?

Are industrial trucks operating in areas where flammable gases or vapors, or combustible dust or ignitable

fibers may be present in the atmosphere, approved for such locations?

Are motorized hand and hand/rider trucks so designed that the brakes are applied, and power to the drive

motor shuts off when the operator releases his/her grip on the device that controls the travel?

Are industrial trucks with internal combustion engine operated in buildings or enclosed areas, carefully

checked to ensure such operations do not cause harmful concentration of dangerous gases or fumes?

SPRAYING OPERATIONS

Is adequate ventilation assured before spray operations are started?

Is mechanical ventilation provided when spraying operation is done in enclosed areas?

When mechanical ventilation is provided during spraying operations, is it so arranged that it will not circulate

the contaminated air?

Is the spray area free of hot surfaces?

Is the spray area at least 20 feet from flames, sparks, operating electrical motors and other ignition sources?

Are portable lamps used to illuminate spray areas suitable for use in a hazardous location?

Is approved respiratory equipment provided and used when appropriate during spraying operations?

Do solvents used for cleaning have a flash point of 100E F or more?

Are fire control sprinkler heads kept clean?

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19