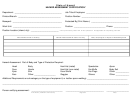

Hazard Assessment Checklist Page 13

ADVERTISEMENT

If you have a fire alarm system, is it certified as required?

If you have interior standpipes and valves, are they inspected regularly?

If you have outside private fire hydrants, are they flushed at least once a year and on a routine preventive

maintenance schedule?

Are fire doors and shutters in good operating condition?

Are fire doors and shutters unobstructed and protected against obstructions, including their counterweights?

Are fire door and shutter fusible links in place?

Are automatic sprinkler system water control valves, air and water pressures checked weekly/periodically as

required?

Is maintenance of automatic sprinkler system assigned to responsible persons or to a sprinkler contractor?

Are sprinkler heads protected by metal guards, when exposed to physical damage?

Is proper clearance maintained below sprinkler heads?

Are portable fire extinguishers provided in adequate number and type?

Are fire extinguishers mounted in readily accessible locations?

Are fire extinguishers recharged regularly and noted on the inspection tag?

Are employees periodically instructed in the use of extinguishers and fire protection procedures?

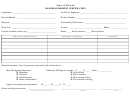

HAZARDOUS CHEMICAL EXPOSURES

Are employees trained in the safe handling practices of hazardous chemicals such as acids, caustics, and the

like?

Are employees aware of the potential hazards involving various chemicals stored or used in the workplace--

such as acids, bases, caustics, epoxies, and phenols?

Is employee exposure to chemicals kept within acceptable levels?

Are eye wash fountains and safety showers provided in areas where corrosive chemicals are handled?

Are all containers, such as vats and storage tanks labeled as to their contents--e.g. "CAUSTICS"?

Are all employees required to use personal protective clothing and equipment when handling chemicals (i.e.

gloves, eye protection, and respirators)?

Are flammable or toxic chemicals kept in closed containers when not in use?

Are chemical piping systems clearly marked as to their content?

Where corrosive liquids are frequently handled in open containers or drawn from storage vessels or pipelines,

is adequate means readily available for neutralizing or disposing of spills or overflows properly and safely?

Have standard operating procedures been established and are they being followed when cleaning up chemical

spills?

Where needed for emergency use, are respirators stored in a convenient, clean and sanitary location?

Are respirators intended for emergency use adequate for the various uses for which they may be needed?

Are employees prohibited from eating in areas where hazardous chemicals are present?

Is personal protective equipment provided, used and maintained whenever necessary?

Are there written standard operating procedures for the selection and use of respirators where needed?

If you have a respirator protection program, are your employees instructed on the correct usage and

limitations of the respirators?

Are the respirators NIOSH approved for this particular application?

Are they regularly inspected and cleaned sanitized and maintained?

If hazardous substances are used in your processes, do you have a medical or biological monitoring system in

operation?

Are you familiar with the Threshold Limit Values or Permissible Exposure Limits of airborne contaminants and

physical agents used in your workplace?

Have control procedures been instituted for hazardous materials, where appropriate, such as respirators,

ventilation systems, handling practices, and the like?

Whenever possible, are hazardous substances handled in properly designed and exhausted booths or similar

locations?

Do you use general dilution or local exhaust ventilation systems to control dusts, vapors, gases, fumes,

smoke, solvents or mists which may be generated in your workplace?

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19