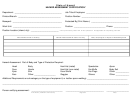

Hazard Assessment Checklist Page 5

ADVERTISEMENT

Are all cord-connected, electrically operated tools and equipment effectively grounded or of the approved

double insulated type?

Are effective guards in place over belts, pulleys, chains, and sprockets, on equipment such as concrete

mixers, air compressors, and the like?

Are portable fans provided with full guards or screens having openings 1/2 inch or less?

Is hoisting equipment available and used for lifting heavy objects, and are hoist ratings and characteristics

appropriate for the task?

Are ground-fault circuit interrupters provided on all temporary electrical 15 and 20 ampere circuits, used during

periods of construction?

Are pneumatic and hydraulic hoses on power-operated tools checked regularly for deterioration or damage?

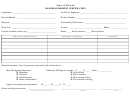

ABRASIVE WHEEL EQUIPMENT GRINDERS

Is the work rest used and kept adjusted to within 1/8 inch of the wheel?

Is the adjustable tongue on the top side of the grinder used and kept adjusted to within 1/4 inch of the wheel?

Do side guards cover the spindle, nut, and flange and 75 percent of the wheel diameter?

Are bench and pedestal grinders permanently mounted?

Are goggles or face shields always worn when grinding?

Is the maximum RPM rating of each abrasive wheel compatible with the RPM rating of the grinder motor?

Are fixed or permanently mounted grinders connected to their electrical supply system with metallic conduit or

other permanent wiring method?

Does each grinder have an individual on and off control switch?

Is each electrically operated grinder effectively grounded?

Before new abrasive wheels are mounted, are they visually inspected and ring tested?

Are dust collectors and powered exhausts provided on grinders used in operations that produce large amounts

of dust?

Are splashguards mounted on grinders that use coolant, to prevent the coolant reaching employees?

Is cleanliness maintained around grinder?

POWDER ACTUATED TOOLS

Are employees who operate powder-actuated tools trained in their use and carry a valid operator's card?

Do the powder-actuated tools being used have written approval of the Division of Occupational Safety and

Health?

Is each powder-actuated tool stored in its own locked container when not being used?

Is a sign at least 7" by 10" with bold type reading "POWDER-ACTUATED TOOL IN USE" conspicuously

posted when the tool is being used?

Are powder-actuated tools left unloaded until they are actually ready to be used?

Are powder-actuated tools inspected for obstructions or defects each day before use?

Do powder-actuated tools operators have and use appropriate personal protective equipment such as hard

hats, safety goggles, safety shoes and ear protectors?

MACHINE GUARDING

Is there a training program to instruct employees on safe methods of machine operation?

Is there adequate supervision to ensure that employees are following safe machine operating procedures?

Is there a regular program of safety inspection of machinery and equipment?

Is all machinery and equipment kept clean and properly maintained?

Is sufficient clearance provided around and between machines to allow for safe operations, set up and

servicing, material handling and waste removal?

Is equipment and machinery securely placed and anchored, when necessary to prevent tipping or other

movement that could result in personal injury?

Is there a power shut-off switch within reach of the operator's position at each machine?

Can electric power to each machine be locked out for maintenance, repair, or security?

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19