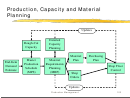

Production, Capacity And Material Planning Page 13

ADVERTISEMENT

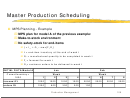

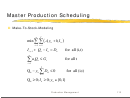

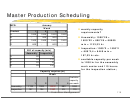

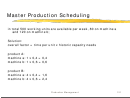

Master Production Scheduling

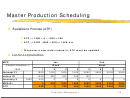

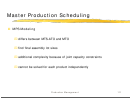

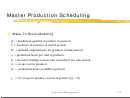

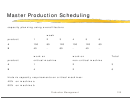

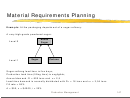

Make-To-Stock-Modeling

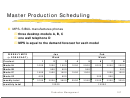

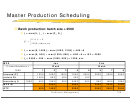

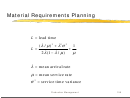

Q =

production quantity of product i in period t

it

I = Inventory of product i at end of period t

it

=

D

demand (requirements) for product i in time period t

it

=

a

production hours per unit of product i

i

=

h

inve

ntory holding cost per unit of product i per time period

i

=

A

set-up cost for product i

i

=

G

production hours available in period t

t

=

>

y

1,if set-up for product i occurs in period t (Q

0)

it

it

Production Management

112

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

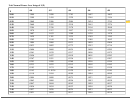

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35 36

36 37

37 38

38 39

39 40

40 41

41 42

42 43

43 44

44 45

45 46

46 47

47 48

48 49

49 50

50 51

51 52

52 53

53 54

54 55

55 56

56 57

57 58

58 59

59 60

60