Aerial Lift Operator Job Performance Measure Form Page 2

ADVERTISEMENT

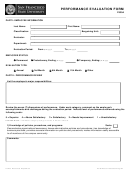

Aerial Lift Operator Job Performance Measure (TQ-AERIAL-P)

Signatures verify a competent demonstration of the 5 performance categories listed below and confidence in the subject operator’s

overall ability to utilize the identified aerial platform/s in a safe manner.

Evaluator Signature: _____________________________________________________

Date: ____________

Candidate Signature: _______________________________________________________

Date: ____________

Supervisor Signature: _____________________________________________________

Date: ____________

Item

Category and Steps

Standard

Rating

01.0

PLANNING & PREPARATION

PERFORMANCE MEASURE

Sat

Unsat

N/A

01.1

Determine aerial platform specifications

Verify unit specifications with supervisor

01.2

Verify rated capacity of the platform to be used

No exceptions

01.3

Check work site conditions, indoors & outdoors (e.g., weather)

Identify all real & potential physical & health hazards

01.4

Ensure personnel T&Q prerequisites are current

No exceptions

01.5

Ensure personnel are fit for duty

No exceptions

01.6

Ensure compliance with ES&H Subject Areas

No exceptions

01.7

Discuss scope of work and job hazards with crew

No exceptions

02.0

HAZARDS & SAFETY CONSIDERATIONS

PERFORMANCE MEASURE

Sat

Unsat

N/A

02.1

Identify the primary aerial platform operator

Only one person to operate the primary controls

02.2

Identify back up operator/s

Know emergency procedures & lowering operation

02.3

Check work surface slope, conditions, weight limits

Verify conditions are with in manufacturer’s limits

02.4

Check travel route and approach clearances

100% accuracy

02.5

Identify overhead electric hazards & safe distance

Verify safe clearance distances or LOTO is in place

02.6

Ensure clearance with overhead obstructions

Headroom clearance is 2 times max height of crew

02.7

Establish a safe work zone via barricades

Restrict and control pedestrian traffic

02.8

Ensure use of PPE & fall protection equipment

Don safety shoes & glasses, hard hat, fall protection

02.9

Check fall protection anchorage points

No exceptions

02.10

Check unit for current maintenance indications

No exceptions

03.0

PRE-OPERATION CHECK

PERFORMANCE MEASURE

Sat

Unsat

N/A

03.1

Ensure manufacturer’s manual is on the unit

Understand manufacturer’s manual, zero exceptions

03.2

Ensure fire extinguisher is on board or at job site

No exceptions

03.3

Read placards, warnings & control markings

Read all placards, warnings & control markings

03.4

Verify platform load is within rated capacity

Adhere to manufacturer guidance

03.5

Check tires, rims & axles

Adhere to manufacturer guidance

03.6

Check platform ladders, hand rungs, fasteners

Adhere to manufacturer guidance

03.7

Check platform structure, guard rails, gates, locks

Adhere to manufacturer guidance

03.8

Check all fluid levels, belts, chains, cables

Adhere to manufacturer guidance

03.9

Check electric systems, components & batteries

Adhere to manufacturer guidance

03.10

Check hydraulic/pneumatic systems & components

Adhere to manufacturer guidance

03.11

Check capacity indicator & movement alarms

Adhere to manufacturer guidance

03.12

Check pothole protectors & out of level warnings

Adhere to manufacturer guidance

03.13

Start engine, check emergency alarms, horns, level indicator

Adhere to manufacturer guidance

03.14

Perform all aerial platform functional checks

Adhere to manufacturer guidance

03.15

Ensure operational readiness or deadline

Complete checklist and make proper determination

03.16

Charge DC battery powered units as necessary

Adhere to manufacturer guidance

03.17

Replace LPG fuel tank as necessary

Adhere to manufacturer guidance

04.0

OPERATING SKILLS

PERFORMANCE MEASURE

Sat

Unsat

N/A

04.1

Mount & dismount safely, use fall protection

Adhere to manufacturer guidance

04.2

Drive and creep/inch forward and reverse

Move 10 feet in a driving mode & creep 1 foot

04.3

Turn 360 degrees right and left using 1 or 2 axles

Minimum disturbance of aerial platform attitude

04.4

Operate from the upper & lower stations

Adhere to manufacturer guidance

04.5

Verify unit balance, stability and attitude

Adhere to manufacturer guidance

04.6

Deploy/setup and store outriggers – see 04.5

Adhere to manufacturer guidance

04.7

Boom up & down, in & out

Minimum disturbance of aerial platform attitude

04.8

Rotate/swing 360 degrees in each directions

Minimum disturbance of aerial platform attitude

04.9

Operate emergency controls with & without power

Adhere to manufacturer guidance

05.0

SECURE THE AERIAL UNIT & WORK AREA

PERFORMANCE MEASURE

Sat

Unsat

N/A

05.1

Secure the unit and work area in a safe manner

Adhere to manufacturer guidance & BNL guidance

Rev: 29 March 2011

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2