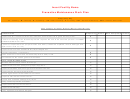

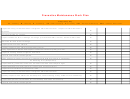

Preventive Maintenance Work Plan Chart Page 16

ADVERTISEMENT

Preventive Maintenance Work Plan

Frequency Key

W – Weekly

M - Monthly Q - Quarterly

SA- Semi-Annually A- Annually SST - Seasonal Start-Up SSH - Season Shut Down

Air Compressors

Critical Tasks

Frequency Status

Date Completed Initials

Drain receiver tank and check traps for proper operation.

SA

Change oil, resume operation and check oil for proper oil level and pressure.

SA

Change oil filter. After replacement, check for leaks.

SA

Change air intake filters.

SA

Check operation of the cut-in and cut-out pressure controls.

SA

Clean and degrease the compressor cooling fins.

SA

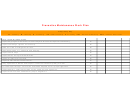

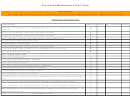

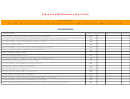

Other recommended tasks

Check and adjust belt tension.

SA

Check belt condition. Replace worn belts with matching sets.

SA

Check sheave alignment and level of shafts.

SA

Check operation of unloader and check valves.

SA

Check high pressure safety relief valve.

SA

Record compressor run times.

SA

Check operation of all safety relief valves.

SA

Inspect coalescent filters and change.

SA

Record pressure reducing valve settings and adjust as required.

SA

Check operation of all valve assemblies as required.

SA

Ensure that lead/lag/sequencing controls are operating compressors efficiently.

SA

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35