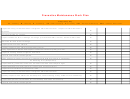

Preventive Maintenance Work Plan Chart Page 24

ADVERTISEMENT

Preventive Maintenance Work Plan

Frequency Key

W – Weekly

M - Monthly Q - Quarterly

SA- Semi-Annually A- Annually SST - Seasonal Start-Up SSH - Season Shut Down

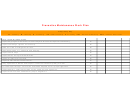

Cooling Towers

Critical Tasks, to be performed during seasonal start-up

Frequency

Status

Date Completed Initials

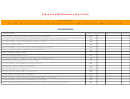

Clean cooling towers by flushing, blowing down all associated piping.

SST

Inspect sprayer heads.

SST

Inspect structural supports.

SST

Inspect and clean louvers.

SST

Inspect collection trays and suction screens for plugging and clean.

SST

Inspect and clean drift eliminators.

SST

Test motor winding continuity on condenser fan motors.

SST

Inspect fans, bearings, housings, protective shields, motors, drives and/or belts. Lubricate as

SST

necessary. Record observations.

Inspect fan motor starters.

SST

Visually inspect motor starter/control center.

SST

Check operation of starter and inspect contact surfaces for wear or pitting.

SST

Check overload settings and check/tighten ALL electrical connections.

SST

Vacuum cabinets to eliminate dust build-up.

SST

Operate gear reducer (where applicable) until oil is warm. Drain oil and refill with new.

SST

Start unit(s) and operate. If applicable, sequence unit(s) through entire operating range.

SST

Record and address any abnormal vibrations.

SST

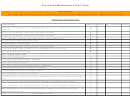

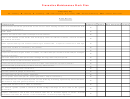

Observe cooling tower to ensure proper operation. Inspect for unusual noise or vibration.

M

Inspect and clean louvers, if required.

M

Check operation of make-up water valve and any associated controls/linkages, lubricate if

M

necessary.

Visually check fan gear reducer/drive oil sample for presence of water and/or sludge.

M

Check oil level in gear reducer/drive (if applicable). Add if required and record amount.

M

Provide Water Treatment.

M

During winter months ensure proper operation of basin heaters, if present.

M

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35