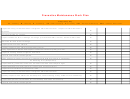

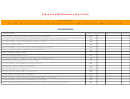

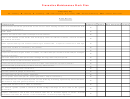

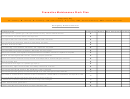

Preventive Maintenance Work Plan Chart Page 23

ADVERTISEMENT

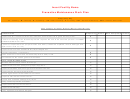

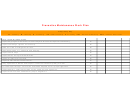

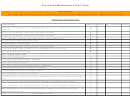

Preventive Maintenance Work Plan

Frequency Key

W – Weekly

M - Monthly Q - Quarterly

SA- Semi-Annually A- Annually SST - Seasonal Start-Up SSH - Season Shut Down

Reciprocating Air Cooled Chillers

Critical Tasks

Frequency Status

Date Completed Initials

Check unit for proper operation, excessive noise or vibration.

M

Run system diagnostics test.

M

Check oil level in sight glass of lead compressor only, add oil as necessary.

M

Check superheat and subcooling temperatures.

A

Check liquid in line sight glass, oil and refrigerant pressures.

M

Check contactors, sensors and mechanical safety limits.

A

Check electrical wiring and connections; tighten loose connections.

A

Clean intake side of condenser coils, fans, and intake screens.

A

Inspect fan(s) or blower(s) for bent blades or imbalance.

A

Lubricate shaft bearings and motor bearings as required.

A

Inspect plumbing and valves for leaks, adjust as necessary.

M

Check evaporator and condenser for corrosion.

M

Clean chiller and surrounding area.

M

Fill out maintenance checklist and report deficiencies.

M

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35