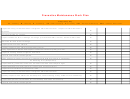

Preventive Maintenance Work Plan Chart Page 3

ADVERTISEMENT

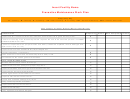

Preventive Maintenance Work Plan

Frequency Key

W – Weekly

M - Monthly Q - Quarterly

SA- Semi-Annually A- Annually SST - Seasonal Start-Up SSH - Season Shut Down

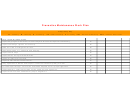

Heating and Ventilation Units

Critical Tasks, to be performed monthly

Frequency Status

Date Completed Initials

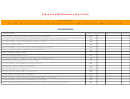

Inspect entire unit for unusual noise and/or vibration, ensure that it is in good working

M

order.

Provide lubrication, if necessary

M

Check that damper linkages are properly connected and operating

M

Inspect piping and fittings for leaks (steam, condensate, hot water, chilled water).

M

Inspect ductwork flexible connectors for abnormalities or leaks.

M

Inspect felt/rubber gaskets around access doors.

M

Following inspection, record observations and deficiencies, if any.

M

Check outside air intake louvers.

M

If problems are identified and unit requires servicing, perform all Non-Critical Tasks for the

M

problematic components.

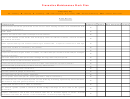

Inspect pre and final filters for abnormal accumulation of dirt and debris, replace if necessary.

Q

Write installation date on new filters.

Clean filter rack and vacuum filter section after removal of old filters and prior to installing new

Q

filters.

Inspect filter rack and ensure that air path does not bypass filters.

Q

Inspect coils (steam, hot water, chilled water) for accumulation of dirt and debris, clean if

Q

necessary.

Inspect/adjust humidifier, if present

Q

Check access doors for tightness.

Q

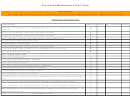

Check fire smoke dampers for proper operation.

A

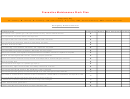

Inspect belts for proper tension and wear (if belts are replaced, record belt type and

A

replacement date on unit)

Inspect entire motor and fan assembly, clean with a damp cloth.

A

Lubricate fan bearings and motors.

A

Lubricate all moving parts/connections, if necessary.

A

Operate dampers over the full modulation range, verify proper operation.

A

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35