Preventive Maintenance Work Plan Chart Page 29

ADVERTISEMENT

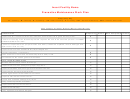

Preventive Maintenance Work Plan

Frequency Key

W – Weekly

M - Monthly Q - Quarterly

SA- Semi-Annually A- Annually SST - Seasonal Start-Up SSH - Season Shut Down

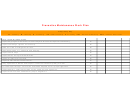

Check low/high water limit controllers, adjust/tighten linkages if necessary. If probe type,

A

ensure that sensors are clean and free of debris.

Inspect boiler safety relief valve and assure proper operation.

A

Ensure proper operation of low/high temperature limit controllers.

A

Tune boiler for operation on the primary fuel. A combustion gas analyzer should be used to

A

check burner efficiency at 25%, 50%, 75% and 100% firing rate.

Other observations should be made during boiler tune-up such as fuel/air ratio, flame

A

color/spread, opacity, stack temperatures and O2/Nox/CO/CO2 concentrations.

Record all observations

A

Ensure that boiler components are operating in proper sequence.

W

Visually inspect all control linkages and components for proper operation, lubricate moving

W

parts, if necessary.

Inspect boiler piping, valves and fitting for leaks.

W

Ensure that boiler pressuretrol set points are not excessively high.

W

Experiment with lowering set points in order to conserve energy while meeting building demand.

W

If problems or inefficient operation are identified correct deficiencies immediately.

W

*Non-destructive testing should be performed on the boilers every three years.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35