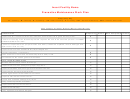

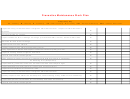

Preventive Maintenance Work Plan Chart Page 28

ADVERTISEMENT

Preventive Maintenance Work Plan

Frequency Key

W – Weekly

M - Monthly Q - Quarterly

SA- Semi-Annually A- Annually SST - Seasonal Start-Up SSH - Season Shut Down

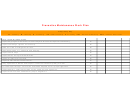

Steam Boilers

Critical Tasks

Frequency Status

Date Completed Initials

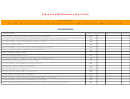

Annual tasks should be performed at the end of each heating season and coordinated with

A

annual boiler inspections.

Boiler Shell

A

Remove the rear and/or side access panel and cleanout.

A

Access the fireside of the boiler and thoroughly clean all internal surfaces, vacuum surfaces

A

and remove all debris.

Clean spaces leading from exhaust breeching to exhaust flue. Inspect for corrosion or damage.

A

Inspect and replace, as necessary, all gaskets.

A

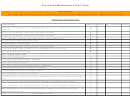

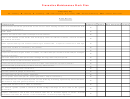

Peripherals

A

Inspect burner natural gas valves, oil valves, air intake damper and back draft damper linkages,

A

adjust if necessary.

Lubricate all burners, damper actuator linkage moving parts and pivot points.

A

Exercise joints and remove excess lubricant.

A

Inspect all fuel solenoid valves for unusual noises, full closure and proper operation.

A

Check fuel cam profile spring for wear, scoring, discoloration.

A

Clean and inspect all fuel oil strainers.

A

Check oil pressure gauge for accuracy.

A

Check actuator motor for proper operation.

A

Check ignition electrode/pilot for proper gap/flame, adjust if necessary.

A

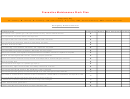

Check/test burner control panel/system for the following indicating lights/safety devices/alarms;

A

flame failure, high/low gas/oil pressure, air switch.

Inspect flame detector lens, clean if necessary.

A

For electric ignition systems, test and record voltage readings on each side of the ignition

A

transformer.

Inspect combustion fan motor and ensure that fan is secured tightly to shaft. Provide

A

lubrication and clean fan blades. If fan is belt driven, check for proper alignment.

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35