Handbook For Basic Process Improvement Page 30

ADVERTISEMENT

Handbook for Basic Process Improvement

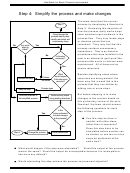

that’s the case, the team may elect to continue trying to improve the process by

entering Step 8 of the Basic Process Improvement Model.

If there are no specification limits for the process, does the shape of the

histogram approximate a bell curve?

After examining the shape created by

plotting the data on the histogram, the team has to decide whether the shape is

satisfactory and whether the data points are close enough to the target value.

These are subjective decisions. If the team is satisfied with both the shape and the

clustering of data points, they can choose to standardize the simplified process or to

continue through the steps of the Basic Process Improvement Model.

From here to the end of the Basic Process Improvement Model, the team is going to use a

scientific methodology for conducting process improvement called the Plan-Do-Check-Act

(PDCA) Cycle. They will plan a change, conduct a test and collect data, evaluate the test

results to find out whether the process improved, and decide whether to standardize or

continue to improve the process. The PDCA Cycle is just that: a cycle. There are no

limitations on how many times the team can attempt to improve the process incrementally.

Plan

Act

(Steps 9 & 10)

(Steps 13 & 14)

Check

Do

(Steps 12 & 13)

(Step 11)

The tools the team needs to assess whether the process is capable are explained in the

following modules of the Basic Tools for Process Improvement :

Module 1:

Operational Definitions

Module 7:

Data Collection

Module 11: Histogram

26

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Business

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35 36

36 37

37 38

38 39

39 40

40