Doe/netl-2012/1540 Mobility And Conformance Control For Carbon Dioxide Enhanced Oil Recovery (Co2-Eor) Via Thickeners, Foams, And Gels - U.s. Department Of Energy Page 133

ADVERTISEMENT

1

1  2

2  3

3  4

4  5

5  6

6  7

7  8

8  9

9  10

10  11

11  12

12  13

13  14

14  15

15  16

16  17

17  18

18  19

19  20

20  21

21  22

22  23

23  24

24  25

25  26

26  27

27  28

28  29

29  30

30  31

31  32

32  33

33  34

34  35

35  36

36  37

37  38

38  39

39  40

40  41

41  42

42  43

43  44

44  45

45  46

46  47

47  48

48  49

49  50

50  51

51  52

52  53

53  54

54  55

55  56

56  57

57  58

58  59

59  60

60  61

61  62

62  63

63  64

64  65

65  66

66  67

67  68

68  69

69  70

70  71

71  72

72  73

73  74

74  75

75  76

76  77

77  78

78  79

79  80

80  81

81  82

82  83

83  84

84  85

85  86

86  87

87  88

88  89

89  90

90  91

91  92

92  93

93  94

94  95

95  96

96  97

97  98

98  99

99  100

100  101

101  102

102  103

103  104

104  105

105  106

106  107

107  108

108  109

109  110

110  111

111  112

112  113

113  114

114  115

115  116

116  117

117  118

118  119

119  120

120  121

121  122

122  123

123  124

124  125

125  126

126  127

127  128

128  129

129  130

130  131

131  132

132  133

133  134

134  135

135  136

136  137

137  138

138  139

139  140

140  141

141  142

142  143

143  144

144  145

145  146

146  147

147  148

148  149

149  150

150  151

151  152

152  153

153  154

154  155

155  156

156  157

157  158

158  159

159  160

160  161

161  162

162  163

163  164

164  165

165  166

166  167

167  168

168  169

169  170

170  171

171  172

172  173

173  174

174  175

175  176

176  177

177  178

178  179

179  180

180  181

181  182

182  183

183  184

184  185

185  186

186  187

187  188

188  189

189  190

190  191

191  192

192  193

193  194

194  195

195  196

196  197

197  198

198  199

199  200

200  201

201  202

202  203

203  204

204  205

205  206

206  207

207  208

208  209

209  210

210  211

211  212

212  213

213  214

214  215

215  216

216  217

217  218

218  219

219  220

220  221

221  222

222  223

223  224

224  225

225  226

226  227

227  228

228  229

229  230

230  231

231  232

232  233

233  234

234  235

235  236

236  237

237  238

238  239

239  240

240  241

241  242

242  243

243  244

244  245

245  246

246  247

247  248

248  249

249  250

250  251

251  252

252  253

253  254

254  255

255  256

256  257

257  258

258  259

259  260

260  261

261  262

262  263

263  264

264  265

265  266

266  267

267 11.

Effects of Process Variables on CO

Foam Mobility Reduction

2

Temperature

Because reservoir temperature is a factor that cannot be altered during a CO

flood, there are

2

relatively few core flooding studies in which temperature is varied systematically. Nonetheless it

o

is apparent that CO

foam flooding at temperatures above 80

C may require more careful design

2

than low temperature floods. There is at least one aspect of high temperature that is favorable:

decreased surfactant adsorption with increasing temperature [Ziegler and Handy, 1979].

However, the primary obstacles for the application of foams in deep, hot formations include the

decrease of surfactant solubility in brine that typically occurs with increasing temperature, the

thermal degradation of the surfactant that is enhanced with increasing temperature [Handy et al.,

1982], the slight increase in the interfacial tension between the CO

and the brine [Liu et al.,

2

o

2005], and diminished foam stability [Wang, 1984] especially at temperatures above 60

C that

must be compensated for by higher concentrations of surfactant [Liu et al., 2005].

Pressure

In general, higher pressure favors CO

foam stability. CO

becomes a more dense solvent at

2

2

higher pressure, which enhances the intermolecular associations between the CO

and the

2

hydrophobic tails of the surfactant molecules. In a micromodel study, it was found that sweep

efficiencies associated with CO

foams flowing at a pressure just below the MMP were just as

2

high as the efficiencies measured at pressures well above the MMP. Therefore, it was concluded

that the high sweep efficiencies can be accomplished using the least CO

if the foam flood is

2

conducted at ~MMP rather than much higher pressures [Chang et al., 1994].

Brine Composition

In general, for a given surfactant, increased salinity (increased TDS) may tend to destabilize

foam or, depending on the surfactant, have little effect. In general, a decrease in foam stability

may be attributable to the increased salinity breaking the foam by decreasing the electrostatic

double layer forces, or by diminishing the surfactant solubility in brine [Alkan et al., 1991].

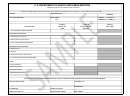

For example, in Figure 11.1, the volume of an air-in-brine foam, in which the “base” brine (1X)

contained 10.58% NaCl and 0.76% CaCl

, tends to decrease with increasing salinity.

2

102

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Legal