Inventory Control Guide Page 4

ADVERTISEMENT

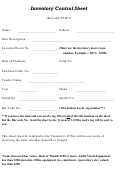

2.1 Control Systems

Motivation for holding inventories

Here we summarize all the reasons which could justify the creation of an inventory.

1.

economy of scale

The first motivation is related to the notion of setup discussed on the previous page.

2.

uncertainty of demand, of delivery, of price

The second main reason is related to the notion of shortage risk also discussed above.

3.

smoothing demand over time

Building inventory is a possible solution to meet a demand which varies over time with a

constant production force. The aggregate planning is a clear illustration of this concept.

4.

flexibility in planning !!!

An inventory of finished goods allows you to modify the production plan as needed. However

the same flexibility can most often be reached by a more efficient way.

Motivation for not holding inventories

The two first aspects were discussed on the previous page.

1.

capital

2.

depreciation - obsolescence - quality

3.

flow time

This last aspect is very important. A large inventory can be seen as a large buffer. Considering

the production plant as a whole, this large buffer increases the flow time and has therefore

many disadvantages.

Decisions

Here are the questions we will try to solve in this chapter.

When to order?

How much - how many to order ?

We will consider different control policies.

Types of control

The first control policy assumes that the inventory is checked permanently. When the

inventory level hits a predefined value (the reorder point R), an order of fixed size Q is then

launched. These policy are usually referred to (Q,R) policies.

With a periodic review, the inventory is checked only at predetermined instants. At these

times, either a fixed (when the review period is short) or a variable quantity can be ordered.

order quantity: Q

Fixed

Variable

Review

Continuous

X

time

Periodic

x

X

Prod 2100-2110

Inventory Control

3

ADVERTISEMENT

0 votes

Related Articles

Related forms

Related Categories

Parent category: Education

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16 17

17 18

18 19

19 20

20 21

21 22

22 23

23 24

24 25

25 26

26 27

27 28

28 29

29 30

30 31

31 32

32 33

33 34

34 35

35 36

36 37

37 38

38 39

39 40

40